What if robots could not only think but also act, seamlessly integrating into hospitals, factories, and farms to tackle humanity’s toughest challenges with unprecedented efficiency? Physical AI, the powerful blend of artificial intelligence and robotics, is no longer a distant dream but a tangible force reshaping industries at breakneck speed. This technology enables machines to interact with the physical world—touching, moving, and building—ushering in an era where efficiency and innovation collide. The implications are staggering, promising solutions to labor shortages and societal needs while raising urgent questions about trust and safety.

The significance of physical AI cannot be overstated in a world grappling with mounting pressures. With a projected shortfall of 1.9 million skilled manufacturing workers in the US by 2033, industries are desperate for automation to fill critical gaps. Beyond economics, this technology addresses vital issues like improving patient care and feeding growing populations through precision agriculture. Understanding its impact is essential for leaders, workers, and consumers alike as it redefines how tasks are performed across sectors.

The Dawn of a Tangible Tech Revolution

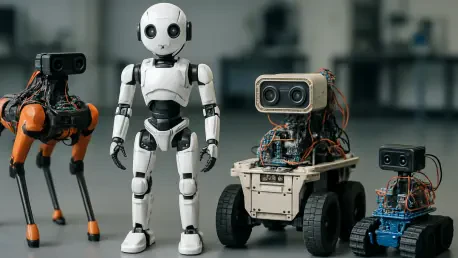

Physical AI marks a pivotal shift from virtual algorithms to machines that operate in real-world environments. Unlike traditional AI, which focuses on data analysis or digital interactions, this innovation empowers robots to execute complex physical tasks with intelligence. From surgical assistants in hospitals to autonomous tractors on farms, the scope of this revolution is vast, signaling a new chapter in technological advancement.

This transformation is happening faster than many anticipated, driven by breakthroughs in machine learning and sensor technology. Companies like Figure AI are already deploying humanoid robots capable of performing intricate tasks in industrial settings. Such developments highlight how quickly physical AI is moving from concept to reality, challenging industries to adapt or risk falling behind.

The excitement surrounding this shift is tempered by critical concerns. As machines become more integrated into daily life, questions about safety, ethics, and job displacement emerge. Addressing these issues is just as important as the technology itself, setting the stage for a balanced exploration of its potential and pitfalls.

Why Physical AI Matters Now More Than Ever

Global challenges like labor shortages and rising demands for efficiency have made physical AI a pressing necessity. In healthcare, overstretched hospitals rely on robots to handle repetitive tasks, allowing staff to focus on patient care. This isn’t a luxury but a response to real-world crises where human resources are stretched thin.

Beyond immediate needs, the technology offers long-term benefits for sustainability and growth. In agriculture, autonomous systems equipped with imaging data optimize crop yields to meet the food demands of a burgeoning population. Similarly, logistics operations use robotic sorting to keep pace with the relentless rise of e-commerce, ensuring goods reach consumers swiftly.

The urgency to adopt physical AI is underscored by economic forecasts. With millions of jobs potentially unfilled in the coming years, automation provides a viable path forward. Its ability to address both current bottlenecks and future demands positions it as a cornerstone of industrial strategy, compelling stakeholders to take notice.

How Physical AI Is Reshaping Key Sectors

Across industries, physical AI is driving unprecedented change with tailored applications. In healthcare, robots disinfect spaces, deliver medications, and assist in surgeries, significantly reducing human error and workload. Exoskeletons also empower patients with mobility issues, showcasing the technology’s human-centered potential.

Manufacturing and agriculture are equally transformed by robotic integration. Factories deploy automated assembly lines to counter workforce shortages, while farmers use self-driving tractors for precise harvesting, maximizing output with minimal labor. Retail giants leverage robots for inventory management, ensuring shelves are stocked efficiently, while logistics firms optimize package sorting for faster deliveries.

The automotive sector stands out with its push toward autonomous fleets, redefining transportation. Early adopters like Agility Robotics demonstrate scalability with robots that navigate complex environments. These examples collectively signal a global shift, where physical AI isn’t just an experiment but a fundamental retooling of operational models across the board.

Building Trust and Credibility in Physical AI

Trust remains a critical barrier to the widespread acceptance of physical AI, especially as robots share human spaces. A robotics expert emphasizes, “Safety and transparency are non-negotiable when machines interact physically with people.” Public sentiment, backed by studies showing a preference for human-in-the-loop systems, reflects a desire for oversight, as seen in AI-assisted aviation rather than fully autonomous control.

Real-world experiences further illustrate this journey from doubt to acceptance. Hospital staff, initially skeptical of delivery robots, grew to rely on them after witnessing fewer errors in medication transport. Such anecdotes reveal that trust is built through consistent performance and visible benefits, not just promises.

Overcoming skepticism requires more than functionality; it demands ethical frameworks. Ensuring that systems prioritize human safety and accountability is paramount. Without this foundation, even the most advanced robots risk rejection, underscoring the need for deliberate efforts to foster confidence among users and communities.

Practical Strategies for Embracing Physical AI

Organizations aiming to integrate physical AI must adopt actionable approaches to ensure success. A primary step is securing AI-ready data, as accurate and reliable datasets are crucial for precision tasks like robotic surgery. Poor data quality can lead to catastrophic failures, making this a non-negotiable priority for any deployment.

Transparency and human oversight form another cornerstone of adoption. By designing systems where humans remain the final decision-makers, as seen in industrial operations, businesses can mitigate risks and build trust. Governance models that clearly outline accountability further reinforce this trust, ensuring that technology augments rather than replaces human judgment.

Focusing on value-driven applications offers a clear path to measurable impact. Deploying robots to enhance factory safety or reduce hospital delivery times provides tangible benefits that justify investment. Tracking outcomes, such as a 30% reduction in medical supply delays, helps organizations refine their strategies, paving the way for broader implementation while maintaining a focus on societal good.

Looking back, the journey of physical AI revealed both its transformative power and the hurdles it faced. Reflecting on its integration, the path forward demanded strategic action—prioritizing robust data systems, embedding trust through oversight, and targeting high-impact use cases. Industries that embraced these principles stood poised to lead, while others risked stagnation. The next steps involved scaling these efforts globally, ensuring that policies evolved alongside technology to safeguard human values. This era of robotics challenged society to balance innovation with responsibility, setting a precedent for future advancements.