In an era where the electronics industry faces unprecedented challenges in managing vast amounts of data across fragmented systems, a groundbreaking partnership between Supplyframe and Orbweaver emerges as a beacon of innovation, promising to revolutionize the sector. These two companies, each a leader in their respective domains, have united to address the critical need for seamless data integration and digital transformation. Supplyframe, known for its Design-to-Source Intelligence (DSI) platform, and Orbweaver, a specialist in data automation and integration, aim to revolutionize how manufacturers and distributors navigate the complexities of design, sourcing, and sales processes. Their collaboration promises to break down longstanding barriers, streamline operations, and equip businesses with the tools needed to thrive in a highly competitive market. This strategic alliance is not just a response to current industry pain points but a forward-looking solution designed to reshape the future of electronics with efficiency and agility at its core.

Overcoming Data Fragmentation Challenges

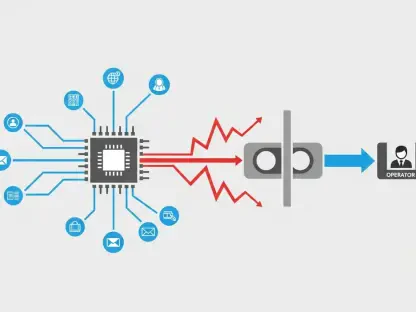

The electronics sector has long been plagued by disconnected data systems that hinder efficiency and create operational bottlenecks. Engineering teams, sourcing departments, and commercial units often operate in silos, resulting in misaligned information, costly delays, and missed market opportunities. Supplyframe and Orbweaver are stepping into this fray with a shared mission to harmonize critical data across these disparate systems. By leveraging Supplyframe’s DSI platform, which processes billions of data signals related to design intent and supply risks, alongside Orbweaver’s Forge and DataHub solutions for API integration and real-time data normalization, the partnership offers a robust framework for connectivity. This integration ensures that trading partners and internal teams can access unified, accurate data, eliminating the friction that has historically slowed down decision-making and innovation in the industry.

Beyond simply linking systems, the collaboration focuses on transforming how data is utilized to drive results. For instance, a manufacturer struggling to align design specifications with sourcing availability can now tap into real-time, harmonized information through the combined platforms. This capability reduces errors and accelerates project timelines significantly. Distributors, too, benefit from enhanced pricing accuracy through Supplyframe’s Configure, Price, Quote (CPQ) tools, paired with Orbweaver’s automation features, allowing for quicker responses to customer needs. The emphasis here is on creating a seamless flow of information that empowers businesses to operate with greater precision and speed, addressing a fundamental challenge that has long impeded progress in the electronics value chain. This targeted approach marks a pivotal shift toward operational cohesion.

Pioneering Digital Transformation in Electronics

Digital transformation remains a pressing imperative for electronics companies striving to stay competitive in a rapidly evolving landscape. The pressure to adopt smarter, more connected methods for managing complex product and supply data has never been higher, as businesses seek to improve transparency and decision-making capabilities. Supplyframe and Orbweaver are at the forefront of this shift, offering integrated tools that catalyze industry evolution. Their partnership combines Supplyframe’s intelligence-driven solutions with Orbweaver’s expertise in data mapping and automation, creating a powerful ecosystem that enhances operational visibility. This synergy enables companies to make proactive, informed decisions, potentially leading to improved profit margins and a stronger return on investment for those willing to embrace these advanced digital strategies.

Looking ahead, the collaboration is designed to ensure that businesses are not only equipped for today’s demands but are also prepared for future complexities. As supply chains become increasingly intricate, the need for scalable and adaptable systems grows. The integrated platforms from Supplyframe and Orbweaver prioritize interoperability, allowing companies to connect with emerging technologies and scale operations as needed. This forward-thinking design helps mitigate risks associated with technological obsolescence, positioning customers to navigate the challenges of tomorrow with confidence. By focusing on long-term adaptability, the partnership underscores a commitment to sustaining competitiveness in an industry where change is the only constant, offering a blueprint for enduring success in digital transformation.

Prioritizing Tangible Benefits for Customers

At the core of the Supplyframe and Orbweaver alliance lies a dedication to delivering measurable outcomes for their customers. The electronics industry demands solutions that provide faster time-to-value and improved data accuracy, and this partnership is tailored to meet those needs. Whether it’s a supplier optimizing direct materials spend or a distributor streamlining quoting processes, the combined solutions address real-world pain points with precision. The integration of Supplyframe’s specialized SaaS tools, like NPI (New Product Introduction) and CPQ, with Orbweaver’s automation platforms ensures that workflows across the value chain—from design to sales—are not only connected but also optimized for efficiency. This customer-centric focus aims to translate technological advancements into practical benefits that enhance day-to-day operations.

Moreover, the partnership seeks to empower businesses with the agility required to respond to market shifts swiftly. Enhanced data accuracy means fewer errors in critical processes, while streamlined digital workflows reduce the time spent on manual tasks. For example, a manufacturer can expedite product launches by accessing synchronized data between design and sourcing teams, while a distributor can improve customer satisfaction through faster, more accurate pricing. These tangible improvements are not just incremental; they represent a fundamental rethinking of how electronics companies can operate at peak performance. By prioritizing results over mere innovation for innovation’s sake, Supplyframe and Orbweaver are setting a new benchmark for what technology partnerships can achieve in delivering value to their clients.

Redefining Industry Collaboration Standards

The alliance between Supplyframe and Orbweaver serves as a compelling example of how specialized providers can unite to address multifaceted industry challenges. By merging Supplyframe’s deep market insights and intelligence resources with Orbweaver’s technical expertise in data integration and automation, this partnership creates a solution that is greater than the sum of its parts. It reflects a broader trend in the electronics sector, where collaborative efforts are increasingly seen as essential for overcoming integration barriers and unlocking the full potential of digital tools. This model of synergy highlights the power of combining complementary strengths to tackle complex issues, offering a framework that could inspire similar cooperative ventures across other technology-driven industries.

Additionally, the collaboration sets a precedent for innovation through strategic teamwork, demonstrating that niche markets can benefit immensely from such alliances. The focus on creating comprehensive, tailored solutions for the electronics value chain showcases a nuanced understanding of industry-specific needs. This approach not only addresses immediate operational challenges but also paves the way for future advancements by fostering an environment of shared progress. As other sectors observe the impact of this partnership, it may encourage a shift toward more collaborative models, where specialized expertise is pooled to drive meaningful change. The success of this endeavor could very well redefine how technology providers approach problem-solving in highly specialized fields.

Building Momentum for Future Impact

Reflecting on the strides made by Supplyframe and Orbweaver, their partnership marks a significant milestone in tackling the persistent issues of data integration within the electronics industry. Their combined efforts successfully bridge critical gaps between design, sourcing, and commercial systems, setting a foundation for enhanced efficiency. Moving forward, the industry can look to this collaboration as a catalyst for further innovation, with a clear path toward adopting more integrated and intelligent systems. Companies are encouraged to explore how such synergies can be applied to their own operations, leveraging these advancements to improve agility and competitiveness. The focus should now shift to scaling these solutions, ensuring broader access to tools that streamline workflows and enhance decision-making, while continuing to adapt to emerging challenges in the ever-evolving electronics landscape.