In the realm of digital twin technology, Chloe Maraina stands as a testament to the power of blending data science with business intelligence. Today, she delves into the intricacies of creating sophisticated digital twins using platforms like Microsoft Fabric, offering her insights into the evolution, challenges, and potential that this technology holds for modern industries.

Can you explain what digital twins are and their importance in modern control systems?

Digital twins serve as digital replicas of physical systems, allowing for powerful simulations and predictive analyses. They play a crucial role in modern control systems by enabling real-time monitoring and optimizing operations. By reflecting the state of real-world systems, digital twins help in predictive maintenance and operational efficiency, minimizing downtime and enhancing decision-making.

How have digital twins evolved from their initial concept to now being used for modeling complete industrial processes?

Initially, digital twins were limited to simple systems with basic inputs and outputs. Over time, as technology advanced and our understanding deepened, we’ve scaled these models to encompass entire industrial processes. We’ve moved from singular device modeling to creating digital representations of large infrastructures, such as energy-generation systems. This evolution has expanded the potential for efficiencies and insights into complex operations.

What are some of the challenges involved in building digital twins for large-scale, complex systems?

Building digital twins for large-scale systems involves several challenges. One of the main difficulties lies in handling the complexity and diversity of data sources. Additionally, the need for real-time data integration and managing fragmented information within regulatory frameworks can be daunting. Ensuring data fidelity and maintaining accurate models that depict complex relationships and interactions also require sophisticated systems and significant expertise.

How important is real-time data in maintaining the state of a digital twin?

Real-time data is indispensable for digital twins as it ensures that the model reflects the current state of its physical counterpart. Without this continual flow of data, a digital twin would quickly become obsolete and could lead to inaccurate predictions and suboptimal decisions. Real-time data allows for immediate response to changes, helping industries maintain operational efficiency and competitiveness.

Why is a large time-series storage environment necessary for delivering large-scale digital twins?

A large time-series storage environment is crucial because it handles the vast amounts of data generated by the components of complex systems over time. This storage supports the fidelity needed for accurate simulations and predictions across different query interfaces. It ensures that digital twins can deliver insights into the system dynamics and historical trends necessary for strategic planning and operational efficiencies.

What role does Microsoft Fabric play in creating digital twins?

Microsoft Fabric provides a comprehensive platform for building and managing digital twins. It integrates various data streams, including real-time and time-series data, within large-scale data lakes. Fabric’s digital twin builder offers a low-code development environment, empowering stakeholders to create and manage digital twins without requiring extensive coding expertise. The platform’s capabilities in data handling and integration enhance the fidelity and functionality of digital twins.

How does the new digital twin builder in Microsoft Fabric function, and what are its main features?

The digital twin builder in Microsoft Fabric operates as part of its real-time intelligence tools, emphasizing a low-code approach. Key features include tools for defining ontologies, which map data to real-world concepts, enabling stakeholders to visualize and manage their digital twins. The builder supports various data connectors for seamless integration, providing a collaborative space for developers and subject matter experts to construct effective models.

Could you explain the significance of the ontology in Microsoft Fabric’s digital twin builder?

Ontology plays a fundamental role in organizing and mapping data to real-world systems within Fabric’s digital twin builder. It establishes a structured vocabulary that defines relationships between entities, making it easier to develop accurate digital models. This structured approach not only facilitates precise data classification but also enhances the ability to generate actionable insights from complex datasets.

How do the built-in data connectors in Fabric assist in building digital twins?

Fabric’s built-in data connectors streamline the integration of diverse data sources required for digital twin modeling. They allow seamless access to various datasets stored across different platforms, ensuring that all relevant information is available for creating comprehensive models. These connectors help maintain the integrity and accuracy of the data which is vital for the effective operation of digital twins.

What are the benefits of using a low-code development platform for creating digital twins?

Using a low-code development platform like Microsoft Fabric democratizes digital twin creation by allowing non-technical stakeholders to participate in the building process. This approach speeds up development times, reduces the need for extensive programming skills, and fosters collaboration among project teams. It empowers businesses to innovate faster and adapt to changing operational needs more easily.

How do entities and their relationships contribute to building a digital twin in Fabric?

In Fabric, entities such as machines, processes, and personnel form the core of a digital twin model. Defining the relationships among these entities is crucial as it replicates the interactions occurring in the real world. This interconnectedness enables the digital twin to provide more accurate predictions and insights, reflecting the dynamic nature of the system it’s modeling.

What kinds of data sources are typically involved in digital twin modeling, and how are they managed in Fabric?

Digital twin modeling typically involves data from IoT devices, ERP systems, equipment logs, and environmental sensors. In Fabric, these data types are managed without extensive ETL processes, thanks to its lakehouse architecture. Data is stored in its native format, allowing queries to work across the data lake efficiently, facilitating integration and ensuring high data fidelity.

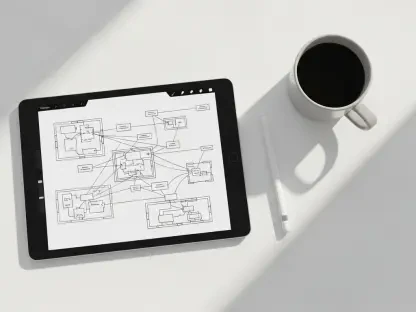

How does the semantic canvas work in the context of the digital twin builder in Fabric?

The semantic canvas serves as a workspace for defining and managing entities within a digital twin. By mapping data to entities and establishing relationships, this tool creates a hierarchically organized model that represents the real-world system. The semantic canvas allows users to visualize and interactively refine the digital twin, making it integral to the modeling process.

Can you describe the process of mapping data to entities in the semantic canvas?

Mapping data to entities in the semantic canvas involves associating data points with specific entities, defining their types and instances. Users create entities that represent real-world objects or processes, then link relevant data using Fabric’s ontology framework. This methodical approach ensures that the model accurately reflects the operational environment and can adapt to changes in real-time.

How can Power BI be used in conjunction with digital twins built on Fabric?

Power BI integrates seamlessly with Fabric, offering robust tools for visualizing and analyzing digital twin data. It allows users to create intuitive dashboards and reports that present insights drawn from the digital twin models. By leveraging Power BI, businesses can gain a clearer understanding of operations, predict potential issues, and make data-driven decisions.

What role do alerts and dashboards play in monitoring and managing digital twins?

Alerts and dashboards are pivotal for the proactive management of digital twins. Dashboards provide real-time visualizations of data, helping teams monitor system status and performance at a glance. Alerts notify users of anomalies or potential issues, enabling quick responses that can prevent downtime or failures. Together, they enhance situational awareness and operational control.

How can machine learning models be integrated with digital twin data to enhance predictive capabilities?

Integrating machine learning models with digital twin data enables predictive analytics, allowing for advanced forecasting and optimization. Models can analyze patterns in the data to predict failures or identify opportunities for improvement. This integration supports the development of strategies for preventative maintenance and operational adjustments, ultimately improving system reliability and efficiency.

What are some examples of the insights or optimizations gained from using digital twins in industrial settings?

Digital twins in industrial settings can yield numerous insights. For instance, in manufacturing, they can optimize production schedules by simulating different scenarios. In energy industries, digital twins can enhance resource allocation and predict equipment maintenance needs. These insights lead to improved efficiency, reduced costs, and minimized environmental impact, reflecting the transformative potential of this technology.

How does the digital twin builder in Fabric help in minimizing downtime or adjusting to changes in demand?

Fabric’s digital twin builder facilitates the real-time simulation and monitoring of systems, enabling managers to anticipate and respond to fluctuations in demand or operational anomalies. By predicting failures and optimizing resource use, businesses can schedule maintenance during low-impact periods and swiftly adjust operations to meet demand changes, thereby minimizing downtime and maximizing productivity.

Can you discuss the overall impact of digital twins on business processes and operational efficiencies?

Digital twins significantly enhance business processes by providing a comprehensive view of operations, enabling proactive management. They improve operational efficiency by predicting and preventing issues, optimizing resource use, and facilitating strategic planning. This leads to cost savings, higher productivity, and greater agility in adapting to market changes, making digital twins a valuable asset in today’s competitive landscape.

Do you have any advice for our readers?

Embrace the journey of digital transformation. While digital twins are powerful tools, it’s essential to invest time in understanding your data and the systems you’re modeling. Collaboration across departments and leveraging platforms like Microsoft Fabric can enhance outcomes, but success ultimately relies on clear goals and strategic execution.