In an era where the manufacturing sector faces mounting pressures from fluctuating costs and operational inefficiencies, a groundbreaking student project has emerged as a beacon of innovation, demonstrating how artificial intelligence can tackle real-world financial challenges. Andrew Smith, a nontraditional student majoring in artificial intelligence in operations at a prominent university, has developed a predictive model that identifies potential financial losses in manufacturing projects with remarkable accuracy. By leveraging data from a former employer, this initiative not only fulfilled academic requirements but also offered actionable insights for industry application. The project stands as a testament to the power of blending classroom learning with practical problem-solving, shining a light on how educational endeavors can directly address pressing business needs. This intersection of academia and industry reveals a promising path forward, where students can play a pivotal role in shaping operational strategies through cutting-edge technology.

Bridging Academia and Industry with Real Data

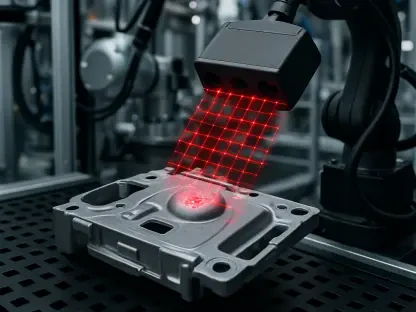

The significance of Smith’s project lies in its use of authentic data drawn from a real manufacturing environment, a stark contrast to the often-simplified datasets used in many academic exercises. This approach introduced the kind of complex, messy variables that professionals encounter daily, providing a more realistic training ground for problem-solving. Engineering managers familiar with the project have noted that such exposure prepares students far better for the workforce than theoretical models ever could, as it forces them to grapple with unpredictable challenges. Smith’s work specifically targeted financial risks by analyzing machine types, production quantities, and failure rates to predict which projects might incur losses. Achieving a 70 percent accuracy rate, the model proved its potential to guide resource allocation and risk management strategies. This success underscores a growing recognition within educational circles that integrating real-world problems into curricula can yield benefits for both students and the industries they aim to serve, fostering a symbiotic relationship.

A Lasting Impact on Business Efficiency

Reflecting on the outcomes of this initiative, the collaboration between Smith and his former employer highlighted a powerful synergy that benefited both parties in tangible ways. The predictive model not only met academic goals but also provided the company with a tool to pinpoint high-risk areas for targeted intervention, ultimately enhancing operational efficiency. Positive feedback from industry professionals validated the practical utility of the model, while Smith’s dedication to refining it further with more intricate data over subsequent months demonstrated a commitment to excellence. This case served as a compelling example of how student-driven innovation could address critical business challenges while equipping learners with invaluable skills. Looking ahead, such projects pave the way for broader adoption of similar partnerships, encouraging educational institutions to prioritize practical applications of technology. The momentum from this effort suggests a future where academia and industry work hand in hand to solve complex problems with real-world impact.