In the high-stakes arena of UK manufacturing, where every second can mean the difference between profit and loss, harnessing real-time data has emerged as a pivotal strategy for staying competitive. Machines, production lines, and logistics networks churn out vast streams of information every day, holding the promise of unprecedented efficiency. Yet, the challenge isn’t merely gathering this data—it’s transforming it into meaningful action before opportunities slip away. Statistics paint a sobering picture: while a significant majority of manufacturers understand the importance of immediate data, nearly half grapple with integrating it into their workflows. This disconnect between potential and execution creates bottlenecks that hinder automation and growth. Exploring how cutting-edge digital tools and strategic approaches can bridge this gap reveals a pathway to not only boost productivity but also redefine operational success in a demanding industry.

Harnessing Immediate Insights for Operational Edge

Turning the flood of real-time data into a competitive advantage requires more than just collection—it demands focus on what truly matters. A striking 74% of UK manufacturers acknowledge the critical role that instant data plays in driving efficiency, yet 46% struggle with integration challenges that prevent them from capitalizing on it. Much of this information, from machine performance metrics to supply chain updates, remains dormant due to outdated systems or slow processing times. The real opportunity lies in sifting through this deluge to pinpoint actionable insights, such as a sudden equipment glitch or a looming delivery delay. By prioritizing speed and relevance, manufacturers can ensure that vital alerts reach the right teams without delay, minimizing downtime and keeping production on track. This shift in approach is not just about data access but about creating a responsive framework where every piece of information serves a purpose.

Beyond identifying key data points, the emphasis must shift to seamless implementation across complex manufacturing environments. Integration barriers often stem from disparate systems that fail to communicate effectively, leaving valuable insights trapped in silos. For instance, a sensor detecting a fault on a production line holds little value if the alert doesn’t reach maintenance teams in time to prevent a shutdown. Addressing this requires a unified digital ecosystem that connects machines, personnel, and decision-making processes in real time. Such a system ensures that data flows smoothly from source to solution, empowering staff to act decisively. This isn’t merely a technical fix but a strategic overhaul, aligning technology with operational goals to unlock productivity gains that were previously out of reach. The focus on connectivity transforms raw data into a dynamic tool for sustained improvement.

Tackling the Challenge of Information Overload

The overwhelming volume of data generated in manufacturing isn’t the root issue—it’s the lack of clarity in handling it that creates inefficiencies. When every machine and process produces endless streams of information, the temptation to store everything can lead to cluttered systems and spiraling costs, especially with unchecked reliance on cloud storage. This scattershot approach risks burying critical insights under irrelevant details, slowing down decision-making at crucial moments. A more disciplined strategy involves filtering data at the source, ensuring only the most pertinent information is processed and acted upon. By adopting this precision-driven mindset, manufacturers can avoid the pitfalls of bloated infrastructure and instead direct resources toward outcomes that enhance the bottom line, from faster fault detection to streamlined inventory management.

Moreover, overcoming data overload necessitates a cultural shift within organizations to prioritize quality over quantity. Too often, the instinct to hoard data stems from a fear of missing out on potential insights, yet this often results in analysis paralysis where teams are inundated with reports but lack clear direction. Implementing targeted data policies can counteract this, focusing on specific metrics that align with operational priorities, such as production throughput or equipment uptime. This not only reduces system strain but also sharpens focus on actionable results, enabling quicker responses to emerging issues. For example, tracking only key performance indicators for a supply chain can prevent stockouts without the need to monitor every minor fluctuation. Such streamlined practices pave the way for a leaner, more effective use of technology in manufacturing settings, cutting through noise to deliver real impact.

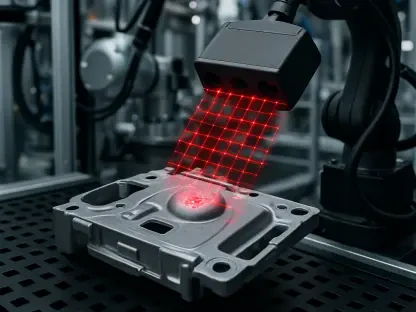

Revolutionizing Speed with Edge Computing

Edge computing stands out as a transformative solution for manufacturers seeking to capitalize on real-time data with minimal delay. Unlike traditional cloud systems that send data to distant servers for processing, edge technology handles information locally—right at the source, whether on a factory floor or within a logistics hub. This drastically cuts latency, allowing for instant detection of issues like a motor overheating or a shipment delay before they escalate into costly disruptions. Additionally, by reducing the volume of data transmitted to centralized clouds, edge computing lowers bandwidth expenses, making it a cost-effective choice. The immediacy of insights empowers production teams to make swift, informed decisions, ensuring operations remain fluid even under tight deadlines or unexpected challenges.

Further enhancing its appeal, edge computing aligns with the need for agility in a fast-moving industry where timing is everything. Consider a scenario where a packaging line sensor identifies a potential jam; with edge processing, the alert reaches operators within seconds, averting a production halt that could cost thousands in lost output. This capability extends beyond isolated fixes—it fosters a proactive environment where teams can anticipate problems rather than merely react to them. The technology also integrates seamlessly with existing systems, providing a scalable solution that grows with a manufacturer’s needs. By bringing computation closer to the point of action, edge computing redefines how data drives efficiency, offering a practical way to stay ahead in a competitive landscape marked by razor-thin margins and high stakes.

Driving Efficiency Through Smart Data Practices

Smart data strategies mark a significant departure from the outdated practice of indiscriminate collection, focusing instead on targeted, meaningful consumption. This approach yields immediate benefits, such as predictive maintenance that allows engineering teams to address equipment issues before failures occur, slashing downtime and repair costs. Similarly, supply chains become more responsive, with reduced inventory overheads achieved by tracking only essential stock levels in real time. Decision-makers gain access to a unified, current snapshot of operations, enabling strategic choices grounded in accurate, timely information. By honing in on data that directly impacts performance, manufacturers can streamline processes and allocate resources more effectively, turning information into a catalyst for measurable progress.

Compliance and risk management also see substantial improvements through smart data practices tailored to local needs. Keeping high-value datasets within controlled environments ensures adherence to stringent standards like ISO 27001, while minimizing exposure to governance pitfalls often associated with broad cloud uploads. This localized focus not only safeguards sensitive information but also curbs operational costs by limiting unnecessary data transfers. For instance, processing critical production metrics on-site prevents the need for constant external validation, maintaining both security and efficiency. As regulatory landscapes grow more complex, such strategies provide a framework for staying compliant without sacrificing speed or innovation. The result is a balanced approach that prioritizes both operational excellence and long-term stability in a heavily scrutinized sector.

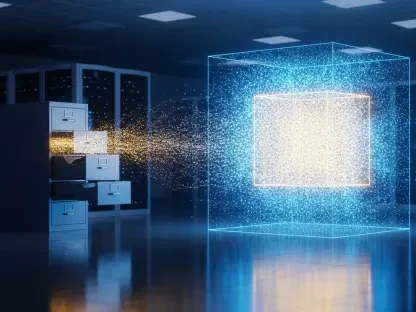

Strengthening Operations with Localized Resilience

Localized data processing offers more than just speed—it builds a robust foundation for operational resilience in the face of external uncertainties. By minimizing reliance on distant cloud infrastructures, manufacturers shield themselves from vulnerabilities like internet outages or third-party service interruptions that can grind production to a halt. This self-sufficient model ensures that critical functions continue uninterrupted, even during connectivity disruptions, which is vital in an industry where delays can ripple through supply chains with devastating effect. Establishing such independence through on-site data handling creates a safety net, allowing UK manufacturers to maintain momentum under pressure and meet tight schedules without compromise.

Looking back, the adoption of localized processing proved to be a turning point for many manufacturers who faced recurring challenges with external dependencies. Reflecting on past disruptions, it became evident that having control over data at the point of origin fortified operations against unforeseen setbacks. The ability to process alerts and analytics directly on the shop floor meant that issues were resolved without waiting for remote server responses. As a forward-looking step, investing in scalable digital infrastructures that support this model remains crucial. Manufacturers are encouraged to explore hybrid setups that blend local processing with selective cloud use, ensuring flexibility while prioritizing resilience. This strategic balance promises not only to sustain productivity gains but also to prepare the industry for evolving demands in an increasingly digital landscape.