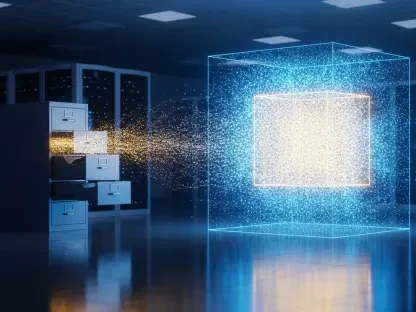

In the rapidly evolving landscape of industrial technology, digital twins have emerged as transformative tools, creating virtual replicas of physical assets or systems for real-time monitoring, simulation, and analysis, thereby revolutionizing how industries operate. These sophisticated models offer unparalleled insights into performance and efficiency, promising to reshape operational strategies. However, the true power of digital twins is unlocked only through effective visualization. By converting vast, complex datasets into clear, intuitive formats, visualization turns raw information into actionable intelligence, bridging the gap between data and decision-making. This critical synergy empowers stakeholders to optimize operations, predict issues, and reduce risks with unprecedented precision. As industries increasingly adopt digital twins to address economic and environmental challenges, understanding the role of visualization becomes essential. This article delves into the ways visualization elevates digital twins, transforming them from mere data repositories into indispensable aids for modern industrial management.

Unlocking the Potential of Digital Twins with Visualization

The concept of a digital twin revolves around a dynamic, data-driven model that mirrors a physical entity, whether it’s a machine, a production line, or an entire facility. Continuously updated with real-time inputs from sensors and other sources, these virtual counterparts provide a window into the performance and behavior of their physical equivalents. Yet, the immense volume of data they generate can overwhelm even the most tech-savvy users. Visualization emerges as the key to making sense of this information. By presenting data through intuitive formats such as charts, dashboards, and interactive 3D models, it enables users to quickly grasp critical insights. Without this visual layer, the potential of digital twins remains largely untapped, as raw data alone lacks the clarity needed for effective interpretation. Visualization, therefore, acts as a bridge, translating abstract numbers into meaningful patterns and trends that drive smarter operational strategies across industrial sectors.

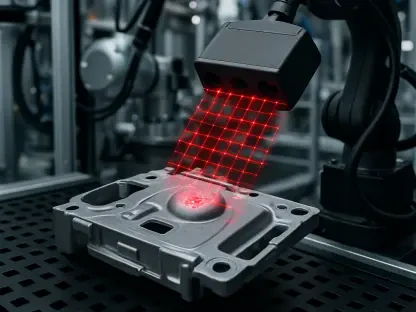

Beyond merely displaying data, visualization enhances the functionality of digital twins by fostering a deeper understanding of complex systems. For instance, a factory manager monitoring equipment health can rely on a well-designed visual interface to instantly spot irregularities that might signal an impending failure. This capability extends beyond immediate diagnostics, allowing for historical analysis to identify recurring issues or simulation of future scenarios to test potential improvements. The impact is profound: decisions that once required hours of data sifting can now be made in moments, significantly boosting efficiency. Moreover, visualization democratizes access to insights, ensuring that stakeholders at all levels—from floor operators to executive leadership—can engage with the digital twin’s outputs. This accessibility transforms the technology into a collaborative tool, aligning teams around a shared, visually clear understanding of operational realities and objectives.

Transforming Data into Decision-Making Power

One of the most compelling benefits of visualization in the context of digital twins is its ability to turn passive data into an active decision-support mechanism. Consider an engineer tasked with overseeing a complex industrial process: a visual dashboard can highlight key performance indicators, flagging inefficiencies or anomalies at a glance. Similarly, a 3D representation might reveal spatial constraints or wear patterns in equipment that raw data alone would obscure. Such visual tools empower users to not only assess the current state of an asset but also anticipate future challenges and evaluate past performance with clarity. This shift from static data collection to dynamic insight generation marks a significant leap in how industries approach problem-solving, ensuring that critical decisions are informed by a comprehensive, easily digestible view of the system’s health and behavior.

Furthermore, visualization within digital twins mitigates the risk of information overload by prioritizing relevance and context. Industrial environments often generate data from multiple sources—sensors, logs, and metadata—creating a deluge that can paralyze decision-making if not managed effectively. Visual tools address this by filtering and organizing data into formats that emphasize what matters most, tailored to the user’s specific role or objective. For example, an operator might focus on detailed process metrics through real-time graphs, while a strategist reviews high-level trends via summary charts. This targeted approach ensures that each stakeholder interacts with the digital twin in a way that maximizes impact, reducing the cognitive load and enhancing response times. As a result, visualization not only clarifies data but also aligns it with actionable outcomes, solidifying the digital twin’s role as a cornerstone of modern industrial efficiency.

Addressing Core Challenges through Visual Solutions

Visualization plays a pivotal role in overcoming several inherent challenges associated with digital twins, ensuring their practical utility in industrial settings. Key among these challenges are accessibility, organization, extrapolation, and flexibility. Accessibility refers to the ease with which users can retrieve and interpret data, eliminating the need to navigate cumbersome systems or archives. Organization tackles the complexity of diverse data types—such as time-series metrics or spatial models—by presenting them in standardized, coherent visual formats. Extrapolation enables users to contextualize an asset’s performance within its broader environment, revealing how internal and external factors interplay. Lastly, flexibility ensures that visual outputs can be customized to suit varied needs, from granular displays for technical staff to summarized overviews for decision-makers. Together, these solutions enhance the usability of digital twins across organizational hierarchies.

Expanding on this, the ability of visualization to address these challenges fundamentally reshapes how industries leverage digital twins for operational excellence. Take accessibility: visual interfaces allow even non-technical users to engage with complex data without requiring deep expertise in data analysis. Organization, meanwhile, transforms chaotic datasets into structured visual hierarchies, making it easier to discern patterns or pinpoint issues. Extrapolation offers a holistic perspective, enabling users to simulate how changes in one part of a system might ripple through others, a capability critical for planning and risk management. Flexibility, perhaps most crucially, ensures that the technology serves a diverse audience, adapting to specific workflows or strategic goals. By resolving these barriers, visualization not only enhances the functionality of digital twins but also broadens their applicability, making them indispensable tools for innovation and efficiency in industrial contexts.

Future Trends and the Evolving Role of Visual Tools

As industries grapple with increasing economic and environmental demands, digital twins are becoming vital for rapid optimization and predictive analytics. However, their effectiveness is intrinsically tied to advancements in visualization. The industrial tech community widely agrees that without robust visual representation, the vast potential of digital twins remains limited, as users struggle to extract meaningful insights from raw data. Looking forward, the growing adoption of digital twins signals a corresponding surge in demand for sophisticated visualization techniques. Innovations in data presentation are expected to play a central role in expanding the utility of digital twins, particularly in areas like predictive maintenance, anomaly detection, and system-wide performance enhancement. This trend underscores the need for continuous development in how data is visually interpreted to meet evolving industrial challenges.

Delving deeper into this trajectory, the future of visualization in digital twins promises exciting possibilities for customization and interactivity. As technology advances, visual tools are likely to become more immersive, incorporating elements like augmented reality to provide real-time, overlaid insights on physical assets. Such developments could revolutionize how operators and managers interact with digital twins, offering intuitive, hands-on experiences that enhance decision-making precision. Additionally, the integration of artificial intelligence with visualization platforms may enable automated anomaly detection and predictive modeling, presented through user-friendly interfaces. This convergence of technologies will further cement visualization as a linchpin of digital twin efficacy, ensuring that industries can harness these tools to stay competitive. As digital twins proliferate across sectors, the emphasis on cutting-edge visual solutions will remain a defining factor in their transformative impact.

Reflecting on Visualization’s Lasting Impact

Looking back, the integration of visualization with industrial digital twins marked a turning point in how data was harnessed for operational success. It shifted the paradigm from grappling with unwieldy datasets to engaging with clear, actionable insights that drove efficiency and innovation. The ability to address challenges like accessibility and flexibility through visual tools proved instrumental in making digital twins practical for diverse industrial applications. Moving forward, the focus should center on fostering advancements in visualization technology to keep pace with the expanding scope of digital twins. Industries would benefit from investing in scalable, user-centric visual solutions that cater to emerging needs, ensuring that these virtual models continue to deliver value. By prioritizing such innovation, the industrial sector can build on past achievements, paving the way for smarter, more responsive systems that tackle tomorrow’s challenges with confidence.