The gleaming, automated production lines of modern factories conceal a dangerous paradox: the very innovations driving unprecedented efficiency are also creating unprecedented levels of risk, transforming the manufacturing sector into the primary target for cybercriminals for four consecutive years. This rapid embrace of artificial intelligence, cloud computing, and the Industrial Internet of Things (IIoT) is fundamentally reshaping how goods are made, but this technological leap is dramatically outpacing the implementation of corresponding cybersecurity measures. As companies race to modernize, they are often building their futuristic operations on insecure digital foundations, leaving them perilously exposed. The tension between the quest for efficiency and the neglected necessity of robust security has created a critical vulnerability gap that threatens not just individual companies, but entire global supply chains. The challenge, therefore, is not to slow innovation, but to fundamentally rethink its implementation.

The Escalating Threat

The High Cost of a Breach

The severe real-world consequences of these digital vulnerabilities were starkly illustrated when a debilitating cyberattack struck automotive giant Jaguar Land Rover. The incident forced a complete production shutdown for an entire month at its highly automated UK facilities, which under normal circumstances produce approximately 1,000 vehicles every single day. The financial fallout from this operational paralysis was staggering. The company reported incurring around $260 million in direct costs related to mitigating the cybersecurity incident. However, this figure was dwarfed by an additional $650 million in losses attributed to the prolonged production disruption, compounded by external factors like U.S. tariffs and the phasing out of older models. This case serves as a potent reminder that the cost of a breach is not limited to the immediate technical response; it encompasses catastrophic business interruption losses that can cripple even the largest and most established industry players, underscoring the critical need for proactive defense.

The impact of the Jaguar Land Rover shutdown was not contained within the company’s own balance sheets; it sent a powerful shockwave across the broader global supply chain, demonstrating the deeply interconnected nature of modern manufacturing. The abrupt cessation of operations threatened the livelihoods of thousands of workers who faced the prospect of layoffs as the assembly lines stood idle. Furthermore, it placed smaller, dependent suppliers in a precarious position, risking their potential bankruptcy due to the sudden halt in business and revenue streams. This single event highlighted a crucial systemic vulnerability: a successful cyberattack on one major manufacturer can rapidly destabilize an entire economic ecosystem. It proves that in today’s integrated industrial landscape, cybersecurity is no longer just a matter of protecting one company’s assets, but a collective responsibility essential for maintaining the health and resilience of the entire value chain, from raw material providers to the end consumer.

The Foundational Flaw

Industry experts unanimously agree that the root of this growing insecurity lies in a fundamental mismatch between new technologies and old infrastructure. The manufacturing sector is aggressively pursuing digitization, driven by the compelling promises of enhanced efficiency, greater profitability, and a reduced reliance on human labor. This trend is quantified by the 2025 Deloitte Smart Manufacturing Survey, which found that among 600 executives at large U.S. manufacturing companies, 57% reported using cloud systems, while 29% are already leveraging AI and machine learning at the facility or network level. Reinforcing this trend, a report from Market Research Future identified North America as the dominant market for cloud-based manufacturing infrastructure, commanding nearly 50% of the global share. However, this rapid technological integration is happening within environments built on legacy operational technology (OT) that was never intended for internet connectivity, creating a perfect storm for cyber threats as old and new systems clash.

This precarious situation arises because older OT systems were engineered for performance and physical isolation, with cybersecurity not being a primary design consideration. As Todd Moore, VP of encryption at Thales, explains, the real challenge is this mismatch where modernization is happening quickly, but the underlying systems were not built with security in mind. This often results in security measures being “bolted on” as a reactive afterthought rather than being integrated from the ground up using “secure-by-design” principles. This reactive approach is inherently flawed, as it attempts to patch vulnerabilities on systems that are fundamentally insecure by nature. Consequently, manufacturers are left highly susceptible to a wide array of cyber threats, from sophisticated ransomware and malware designed to halt production to phishing campaigns targeting employees and denial-of-service attacks aimed at disrupting critical online services. The failure to embed security into the core of digital transformation initiatives creates a fragile and easily exploitable operational environment.

Unpacking the Vulnerabilities

The Widening Attack Surface

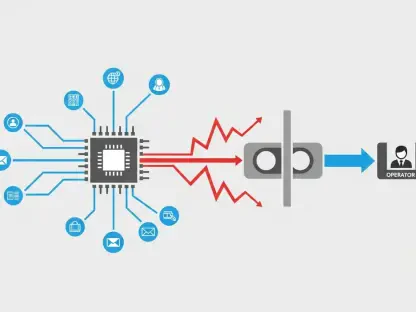

The adoption of artificial intelligence and cloud-based systems dramatically amplifies these inherent risks by massively expanding what cybersecurity professionals refer to as the “attack surface area”—the total number of potential entry points for a cybercriminal. Nick Nolen, vice president of cybersecurity at Redpoint Cyber, notes that a modern manufacturer’s attack surface is far broader and more complex than commonly perceived. It comprises an intricate web of third-party integrators with network access, countless internet-connected machines on the factory floor, a wide array of vendor-supplied software, and the continuous exchange of data between different business units, cloud platforms, and supply chain partners. Each of these interconnected touchpoints represents a potential vulnerability that an attacker can exploit. The sheer scale and complexity of this expanded surface make it exceedingly difficult to monitor and secure effectively, turning the very network that drives efficiency into a landscape of opportunity for malicious actors.

The deeply interconnected nature of these modern manufacturing systems represents a critical weakness that attackers are keen to exploit. An adversary who successfully gains a foothold in one small, seemingly insignificant part of the network—perhaps through a compromised third-party vendor or a single insecure machine—can then move laterally with relative ease toward more critical systems. This ability to traverse the network allows them to escalate their privileges and target high-value assets. As more proprietary and sensitive data, such as intricate design files, secret production formulas, and detailed process information, is migrated to the cloud to power AI algorithms and automation, these cloud environments become increasingly attractive and valuable targets for cybercriminals. The centralization of a company’s “crown jewels” in the cloud raises the stakes of a potential breach from a simple disruption to a potentially catastrophic loss of intellectual property and competitive advantage.

Critical Blind Spots

According to Kevin Albano, global head of X-Force Threat Intelligence at IBM, the single biggest risk facing manufacturers today is the potential for unauthorized access to this highly sensitive data. This danger is significantly compounded by a pervasive lack of transparency throughout the technology supply chain, which creates dangerous blind spots for security teams. Ferhat Dikbiyik, chief research and intelligence officer at Black Kite, points out that many manufacturers do not possess a complete understanding of the components, software libraries, and security protocols embedded within the AI and cloud tools their vendors provide. This opacity means that companies are often unknowingly inheriting the security vulnerabilities of their technology partners. An insecure component in a vendor’s AI model, for instance, could create a backdoor into the manufacturer’s entire network, a risk that is nearly impossible to mitigate without full supply chain transparency and rigorous third-party risk management protocols.

This problem of limited visibility is further exacerbated by the informal, and often unsanctioned, use of technology known as “shadow IT.” Employees, aiming to improve their workflow, may use unapproved AI and cloud tools, uploading sensitive design specifications or proprietary process information without the security team’s knowledge or oversight. This creates significant, unmonitored security gaps. Nick Nolen highlights the critical questions companies must be able to answer to address this risk: “Do you know what your vendor is doing with that data? Do you know where it is stored? How long is it retained? Is it being used to train their own models?” The inability for most organizations to confidently answer these questions signifies a major failure in data governance and a critical security vulnerability. Without clear policies and controls governing data handling by both employees and vendors, manufacturers are essentially operating in the dark, unable to fully grasp where their most valuable information resides or how it is being protected from potential compromise.

Building a Resilient Digital Factory

A Proactive Security Blueprint

Despite the daunting challenges, experts outline a clear, multi-faceted strategy for mitigating these risks, centered on a fundamental shift from a reactive to a proactive security posture. The first and most crucial step, as advised by Kevin Albano, is for manufacturers to begin treating their AI datasets and other intellectual property as crown-jewel assets. This requires implementing a rigorous data governance program that includes classifying all data based on its sensitivity, systematically encrypting all personally identifiable and proprietary information both when it is stored (at rest) and when it is being transmitted (in transit), and establishing strong key management protocols to ensure that only authorized personnel can control access. Echoing this sentiment, Todd Moore emphasizes that thorough data classification is the essential foundational step to understanding precisely where vulnerabilities lie and how to prioritize defensive efforts. Without knowing what data is most valuable, it is impossible to protect it effectively.

To counter the significant risk of a single breach causing a catastrophic, system-wide failure, Ferhat Dikbiyik strongly recommends the implementation of “proper segmentation between IT, cloud, and operational systems.” By creating robust digital barriers between the corporate network (IT) and the factory floor (OT), a company can effectively contain a security incident. This ensures that a compromise in a standard business system, such as an employee’s email account or a cloud-based CRM application, cannot easily cascade into the physical production environment and halt operations. This architectural approach of containment is critical for operational resilience. Such segmentation limits an attacker’s ability to move laterally across the network, transforming a potentially devastating production shutdown into a more manageable and isolated IT incident, thereby preserving the core manufacturing functions of the business while the security team addresses the breach.

A Strategic Realignment

It became clear that the accelerated push toward modernization had inadvertently created a landscape of unforeseen and profound vulnerabilities. Manufacturers came to understand that their digital transformation initiatives demanded a parallel and equally robust security transformation. The prevailing wisdom shifted from viewing security as a cost center to recognizing it as a fundamental enabler of sustainable innovation. The path forward was no longer about choosing between progress and protection; instead, it centered on integrating security into the very fabric of technological advancement. This strategic realignment ensured that the smart factories of the future were designed not only for peak efficiency and productivity but also with an innate resilience that could withstand the sophisticated threats of the digital age. In doing so, these organizations protected not only their own critical operations but also the stability of the entire economic ecosystem they supported.