I’m thrilled to sit down with Chloe Maraina, a trailblazer in the realm of business intelligence with a deep passion for weaving compelling stories through big data. As an expert in data science, Chloe has a keen eye for the future of data management and integration, making her the perfect person to discuss the evolving landscape of AI in industrial and manufacturing sectors. Today, we’ll explore how strategic acquisitions are shaping AI cloud platforms, the impact on research and development in key industries, and the democratization of advanced tools for engineers. We’ll also touch on how these technologies are streamlining workflows and fostering innovation across various domains.

What inspired the recent move to bring Monolith AI into CoreWeave’s ecosystem, and what unique value does this partnership offer?

The acquisition of Monolith AI by CoreWeave is really about creating a synergy that amplifies both companies’ strengths. Monolith brings specialized expertise in AI and machine learning tailored for physics and engineering challenges, which perfectly complements CoreWeave’s robust AI cloud infrastructure. The unique value here is in delivering a platform that can tackle complex industrial problems with speed and precision, something that’s critical for manufacturing and engineering sectors looking to innovate faster.

How do you see this collaboration enhancing CoreWeave’s long-term vision for AI cloud services?

This move aligns seamlessly with CoreWeave’s goal of being a leader in applied AI cloud solutions. By integrating Monolith’s capabilities, we’re not just expanding our technological arsenal; we’re also positioning ourselves to address very specific pain points in industries like manufacturing. Our vision is to create an ecosystem where AI isn’t just a luxury but a practical tool for solving real-world problems, and Monolith’s focus on engineering applications is a big step in that direction.

In what ways do you anticipate this acquisition will transform the experience of industrial and manufacturing customers?

For industrial and manufacturing clients, this acquisition means faster and more efficient processes. Combining Monolith’s machine learning tools with CoreWeave’s powerful cloud platform allows us to significantly cut down R&D timelines. Customers can iterate on designs quicker, test concepts virtually, and bring products to market faster, which is a game-changer in competitive sectors where time is everything.

Can you elaborate on how this integration will specifically optimize product design workflows for these industries?

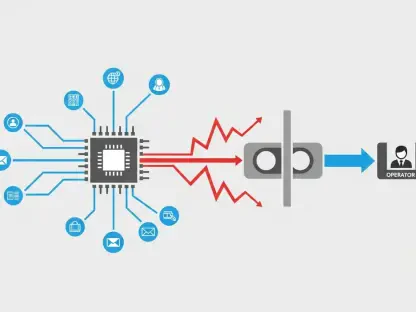

Absolutely. Monolith’s tools are designed to streamline workflows by automating decision-making in the design phase. For instance, features like test plan optimization help engineers figure out the most efficient testing strategies, while anomaly detection identifies potential issues early on. Paired with CoreWeave’s scalable cloud resources, these tools allow for real-time collaboration and data processing, making the entire design process smoother and less resource-intensive.

Monolith AI has a reputation for empowering engineers who aren’t AI experts. How do their tools make complex technology accessible to non-specialists?

Monolith’s platform is built with the end-user in mind, particularly engineers who might not have a background in coding or AI. Their tools are intuitive, integrating directly into existing engineering workflows. Features like anomaly detection or test recommendation systems provide actionable insights without requiring users to understand the underlying algorithms. It’s about lowering the barrier to entry so that AI becomes a practical tool for everyone on the team.

What does this accessibility mean for reducing dependence on physical testing in engineering projects?

It’s transformative. By leveraging Monolith’s simulation-driven machine learning, engineers can run countless virtual tests to predict outcomes and refine designs before ever building a physical prototype. This not only saves time but also cuts costs significantly, as physical testing can be both expensive and time-consuming. It allows for more experimentation in a virtual space, which ultimately leads to better, more innovative products.

Monolith has worked with major players like Nissan, BMW, and Honeywell. How will this acquisition strengthen or expand those relationships?

Partnering with CoreWeave gives Monolith the backing to scale these relationships further. With access to our cloud infrastructure, we can enhance the support and capabilities offered to these companies, ensuring they get even more value from Monolith’s platform. We’re also looking to deepen these partnerships by exploring new use cases and applications, while keeping the door open to bring similar industries into the fold with tailored solutions.

CoreWeave has been active in the AI cloud space with several strategic additions. How does Monolith fit into this broader portfolio of tools and services?

Monolith is a key piece of the puzzle in our mission to build a comprehensive AI cloud ecosystem. While other recent additions focus on areas like reinforcement learning or experiment tracking, Monolith’s strength lies in its niche focus on engineering and physics-based challenges. It adds a layer of specialization that makes our offerings more versatile, ensuring we can cater to a wide range of industrial needs under one umbrella.

Looking at CoreWeave’s involvement in the automotive sector, such as with the Aston Martin Aramco Formula One Team, how might Monolith’s expertise play a role there?

Monolith’s expertise is incredibly relevant to automotive applications, especially in high-stakes environments like Formula One. Their tools can support advanced simulations and optimizations for vehicle performance, which is critical in a sport where milliseconds matter. We see a lot of potential to apply Monolith’s capabilities to enhance design and testing processes for such partnerships, helping teams push the boundaries of what’s possible on the track.

What is your forecast for the future of AI-driven solutions in industrial and manufacturing sectors over the next decade?

I’m incredibly optimistic about the trajectory of AI in these sectors. Over the next ten years, I expect AI to become deeply embedded in every stage of industrial processes, from ideation to production. We’ll see even greater adoption of tools that democratize AI, making them accessible to smaller firms and not just industry giants. The focus will be on creating seamless, integrated platforms that handle everything from design to supply chain optimization, ultimately driving efficiency and sustainability on a global scale.