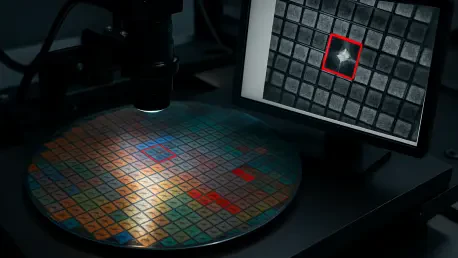

In the high-stakes world of semiconductor manufacturing, where a single missed fault can lead to millions in losses, the demand for cutting-edge anomaly detection has never been more urgent. Each wafer undergoes hundreds of meticulously controlled steps, producing vast streams of sensor data that must be monitored in real time to ensure quality and yield. Traditional methods often fall short, struggling to catch subtle deviations or context-dependent issues amid the noise of complex production environments. Enter a transformative solution from NVIDIA, designed to address these challenges head-on with precision and speed. This innovative technology leverages advanced models to pinpoint anomalies with unprecedented accuracy, offering a lifeline to factories striving to maintain efficiency and profitability. By shifting from reactive to proactive monitoring, this approach promises to redefine how the industry tackles data-intensive challenges, protecting valuable resources and paving the way for smarter, automated systems at scale.

1. Unveiling a Game-Changing Model for Time-Series Tasks

Semiconductor manufacturing stands as a cornerstone of modern technology, yet its complexity poses significant hurdles in maintaining flawless production. NVIDIA NV-Tesseract emerges as a groundbreaking family of models crafted to handle diverse time-series tasks such as anomaly detection, classification, and forecasting within a unified framework. This versatile backbone adapts seamlessly to industries where data evolves rapidly, ensuring relevance across dynamic environments. Specifically tailored for semiconductor fabs, NV-Tesseract addresses the critical need for precision in monitoring vast sensor outputs. From chamber pressures to vibrations, the ability to analyze and act on this data in real time is paramount. By providing a robust foundation, this technology enables factories to move beyond outdated methods, focusing instead on predictive insights that safeguard production quality. The potential to transform operational efficiency is immense, as it equips manufacturers with tools to navigate the intricacies of modern chipmaking with confidence and control.

The significance of NV-Tesseract lies in its adaptability to the unique demands of semiconductor processes, making it a vital tool for the industry. Unlike generic solutions, this model can be fine-tuned to specific tools and production lines, ensuring that anomaly detection aligns with individual operational nuances. Its design prioritizes real-time analysis, a necessity in an industry where delays can compound into catastrophic losses. By integrating with existing systems, it offers a practical upgrade rather than a complete overhaul, easing the transition for manufacturers. Moreover, the framework’s ability to handle multiple correlated sensors simultaneously sets it apart, capturing the interdependent nature of fab data. This comprehensive approach reduces the risk of overlooking subtle faults that might escape traditional monitoring. As a result, fabs gain a powerful ally in maintaining yield, cutting waste, and enhancing automation. The focus on actionable outcomes ensures that this technology is not just theoretical but a tangible step forward for the sector.

2. Navigating the Complexities of Wafer Production

Semiconductor manufacturing is a labyrinth of precision, with each wafer passing through hundreds of steps, each generating extensive sensor data like gas flows, RF power levels, and vibrations, presenting a formidable challenge. This data deluge becomes overwhelming, as even minor deviations can signal impending defects that jeopardize entire batches. Traditional monitoring relies heavily on fixed thresholds and statistical process control (SPC), methods that are inherently reactive and demand frequent recalibration as processes drift over time. Such approaches often fail to detect subtle or context-dependent anomalies, allowing production to continue unchecked until significant damage occurs. The financial impact of these oversights can be staggering, with yield losses running into millions due to a single missed fault. Addressing this gap requires a shift to more dynamic, predictive systems capable of interpreting complex data patterns in real time to prevent costly disruptions.

The limitations of conventional methods underscore the urgent need for innovation in anomaly detection, as fixed thresholds, while straightforward, lack the flexibility to adapt to the nuanced shifts inherent in semiconductor processes, often triggering false alarms or missing critical issues. SPC, though statistically grounded, struggles with the sheer volume and interdependency of sensor data, making it difficult to isolate meaningful signals from background noise. This reactive stance means that by the time an issue is flagged, the damage may already be extensive, requiring costly rework or scrapping of materials. The stakes are heightened in an industry where precision is non-negotiable, and the pressure to maintain high yields drives the search for smarter solutions. A technology that can anticipate rather than merely respond to anomalies offers a lifeline, promising to mitigate risks before they escalate and ensuring that production remains on track without unnecessary interruptions.

3. Precision and Real-Time Insights with Advanced Technology

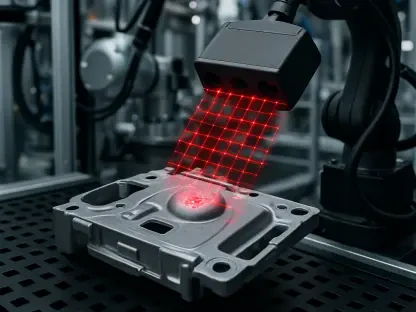

NV-Tesseract, delivered as an NVIDIA NIM microservice, redefines anomaly detection by identifying the precise moment an issue arises within a time-series dataset, whether across a single signal or multiple correlated sensors. This level of granularity is vital for semiconductor fabs, enabling them to determine exactly when wafers may have become faulty and take immediate corrective action. By localizing anomalies in real time, the technology prevents losses from cascading downstream, preserving valuable resources. The shift from after-the-fact inspection to proactive monitoring transforms raw sensor noise into actionable insights, directly impacting operational efficiency. This capability not only protects yield but also slashes costs by minimizing waste and downtime. As a result, fabs can maintain tighter control over production, ensuring that quality standards are upheld without sacrificing speed or scalability in their processes.

Beyond detection, the integration of NV-Tesseract with NVIDIA NIM amplifies its impact by facilitating seamless deployment into existing systems, ensuring that technology can be adopted without major disruptions. The ability to act swiftly on pinpointed anomalies means that equipment can be adjusted or repaired before defects propagate, safeguarding entire production lines. This real-time approach contrasts sharply with traditional methods that often require extensive post-event analysis, during which further damage may occur. Additionally, the focus on correlated sensor data ensures a holistic view of the manufacturing environment, capturing interactions that might otherwise be overlooked. The outcome is a more resilient operation, where automation at the fab scale becomes not just a possibility but a practical reality. By reducing the financial and operational burden of anomalies, this technology empowers manufacturers to push boundaries in innovation, confident that their processes are protected by cutting-edge intelligence.

4. Decoding the Data Intensity of Semiconductor Fabs

Semiconductor manufacturing ranks among the most data-intensive industries globally, with each wafer navigating numerous tightly controlled steps while tools stream data from dozens to hundreds of sensors. This results in not only vast data volumes but also interdependent signals that demand multivariate analysis for meaningful interpretation. A deviation in one sensor might appear trivial in isolation, yet when correlated with others, it can indicate the onset of a severe fault. Common issues include level shifts, where a sensor’s baseline changes suddenly due to calibration or tool drift, and spikes or fluctuations that signal instability in plasma sources or gas flow valves, risking entire wafer batches. Sensor failures, marked by flat or locked values, hide the true process state, while scale shifts—sudden jumps in output magnitude—often stem from misconfiguration or early hardware issues. These patterns highlight the critical need for cohesive data analysis to maintain production integrity.

The complexity of fab data necessitates a departure from siloed monitoring approaches toward systems that can handle interdependencies effectively, ensuring that manufacturers can maintain high standards of quality and efficiency in their operations. Each sensor type contributes unique insights, yet their combined behavior often tells the full story of a process’s health. For instance, a minor fluctuation in gas flow might be benign on its own but catastrophic when paired with a simultaneous dip in chamber pressure. Traditional tools struggle to connect these dots, leaving gaps in detection that can compromise quality. Moreover, the sheer scale of data generated daily in fabs overwhelms manual or rule-based systems, increasing the likelihood of missed anomalies. A technology capable of synthesizing this information in real time offers a transformative advantage, ensuring that potential issues are flagged before they escalate. By addressing these data challenges head-on, manufacturers can achieve greater reliability, protecting both their output and their bottom line from the pitfalls of undetected faults.

5. Key Findings from Dataset Testing

Evaluations of NV-Tesseract on semiconductor fab datasets reveal a pivotal insight: anomaly localization is just as crucial as detection itself. Traditional SPC charts and tool alarms often raise alerts without specifying when a process veered off course, forcing fabs to scrap larger lots than necessary or conduct expensive re-inspections. NV-Tesseract changes this dynamic by identifying the exact timestamp an anomaly begins, providing a clear decision point. Wafers processed before this moment can frequently be salvaged, while those after warrant closer examination. This precision minimizes unnecessary waste, ensuring that only affected products are discarded. Furthermore, it shifts the focus from broad, reactive measures to targeted interventions, streamlining the response process. Such granularity equips manufacturers with a practical tool to manage yield more effectively, addressing a long-standing gap in traditional monitoring approaches.

The dual impact of this technology reshapes operational outcomes in semiconductor production, offering significant improvements in efficiency and cost management. By reducing the volume of discarded products, NV-Tesseract directly cuts material losses, a significant cost factor in the industry. Simultaneously, it enables near-real-time corrective actions, allowing equipment to remain online and preventing defects from spreading downstream. This capability preserves both yield and cost efficiency, addressing two critical priorities for fabs. Unlike conventional alarms that offer vague warnings, NV-Tesseract complements existing systems with contextual intelligence, enabling decisive action at the scale of modern manufacturing. The result is a more agile production environment where resources are conserved, and downtime is minimized. Manufacturers gain not just a detection tool but a strategic asset that enhances their ability to navigate the high-pressure demands of chipmaking, ensuring that quality and profitability remain aligned even under complex conditions.

6. Seamless Integration into Production Systems

Deploying advanced anomaly detection models in semiconductor manufacturing requires more than innovation—it demands scalability and ease of integration into existing production monitoring systems. NVIDIA NIM, part of NVIDIA AI Enterprise, addresses this need as a set of microservices designed for secure, high-performance AI model inferencing across workstations, data centers, and the cloud. Supporting a wide range of AI models, NIM ensures seamless and scalable inferencing whether on-premises or at the edge, using industry-standard APIs. It enables containerized deployment in minutes via the NVIDIA NGC Catalog, runs consistently across diverse environments, and scales to hundreds of microservices with orchestration frameworks like Kubernetes. Built-in health checks, monitoring, and security features, backed by continuous validation and enterprise support, meet stringent performance and reliability requirements for industrial applications.

Delivering NV-Tesseract as a NIM microservice allows fabs to transition swiftly from research prototypes to full-scale production deployments without the burden of custom packaging or complex integration. This streamlined approach eliminates weeks of engineering effort, making advanced anomaly detection accessible to manufacturers of varying technical capacities. The consistency across deployment platforms ensures that whether a fab operates in a local data center or a hybrid cloud setup, the performance of NV-Tesseract remains reliable. Additionally, the focus on security and monitoring within NIM addresses the critical need for data protection in an industry handling sensitive operational information. By bridging the gap between cutting-edge research and practical application, this solution empowers semiconductor manufacturers to adopt sophisticated tools with minimal friction, ensuring that the benefits of real-time anomaly detection are realized without disrupting established workflows or requiring extensive retraining.

7. Step-by-Step Deployment Workflow

Implementing NV-Tesseract through NVIDIA NIM is designed for simplicity, ensuring that semiconductor fabs can integrate advanced anomaly detection with minimal technical overhead, making the process accessible even to those with limited technical expertise. The deployment process for a single-node setup using Docker follows clear, actionable steps. First, retrieve the NV-Tesseract container by pulling it from the NVIDIA repository with the appropriate version number. Next, launch the container with GPU support, mapping local data directories for access and providing necessary API keys to authenticate the service. Finally, configure input and output formats, handling data as CSV or JSON time-series, with outputs including timestamps, sensor values, anomaly scores, metadata, and diagnostics. This structured approach ensures that even complex AI models can be deployed efficiently, allowing manufacturers to focus on operational outcomes rather than technical complexities, thereby accelerating the adoption of cutting-edge monitoring tools.

The flexibility of input and output formats further enhances the usability of NV-Tesseract in diverse fab environments. Input data for multivariate time-series can be formatted as JSON or CSV, with each element containing timestamps in ISO-8601 format and corresponding numeric sensor readings. The output mirrors this structure, returning an array of equal length that includes timestamps in epoch seconds, sensor values, and an anomaly flag—0 for normal and 1 for anomaly. This standardized data handling ensures compatibility with existing systems, reducing the need for extensive reconfiguration. By simplifying the technical barriers to deployment, the workflow enables fabs to test and implement anomaly detection rapidly, gaining immediate insights from their sensor data. The emphasis on accessibility and consistency in this process reflects a commitment to practical innovation, ensuring that advanced technology serves as a tool for progress rather than a source of operational disruption.

8. Turning Data Noise into Operational Strength

Semiconductor fabs generate torrents of sensor data—spanning pressures, flows, temperatures, and vibrations—that hold the potential to signal trouble if interpreted correctly. For decades, engineers have relied on fixed thresholds and manually tuned rules, approaches that struggle under the noise, drift, and scale of modern chipmaking. NV-Tesseract, supported by NVIDIA NIM, charts a forward-looking roadmap to tackle these challenges. This includes custom fine-tuning to adapt the model to specific fab tools, recipes, or production lines, as well as hyperparameter tuning to balance precision and recall based on operational needs. Such advancements ensure that anomaly detection is not a one-size-fits-all solution but a tailored capability that aligns with unique manufacturing contexts. By packaging these features through NIM, they are positioned for scalable deployment, moving beyond research to practical application across extensive tool fleets.

The operational benefits of this technology are multifaceted, directly addressing key pain points in semiconductor production. Early detection of subtle deviations in plasma intensity or gas flow protects wafer yield, preventing scrap before it occurs. Immediate identification of sensor failures or calibration drifts reduces downtime, avoiding extended outages or cascading issues. By minimizing false alarms while highlighting critical events, NV-Tesseract builds trust among engineers in automated monitoring systems. Additionally, scaling intelligence across hundreds of machines with a unified detection framework minimizes integration overhead, speeding adoption. These outcomes transform noisy signals into actionable insights, fortifying operational resilience. Manufacturers gain the ability to maintain high standards of quality and efficiency, leveraging data as a strategic asset rather than a source of uncertainty, and positioning themselves to meet the escalating demands of the industry with confidence.

9. Embarking on a Path to Advanced Monitoring

Semiconductor fabs confront some of the most daunting data challenges in any industry, yet NV-Tesseract and NVIDIA NIM offer a pathway to move advanced anomaly detection from research to production in mere hours. Early access to the NV-Tesseract NIM has been made available, allowing testing in varied environments—on-premises, cloud, or edge—with fab-specific sensor data to uncover critical anomalies. Engagement with NVIDIA follows structured steps: requesting early access through the NVIDIA DGX Cloud team, scheduling a demonstration to witness the technology in action, discussing specific time-series requirements, and exploring integration into anomaly detection workflows. This streamlined process ensures that manufacturers can quickly assess the potential of NV-Tesseract, aligning it with operational needs without prolonged delays. The focus remains on practical implementation, enabling fabs to enhance monitoring capabilities efficiently.

Reflecting on the adoption process, the emphasis has been on empowering fabrication plants to integrate NV-Tesseract NIM as a cornerstone of their monitoring systems, ensuring they can address production challenges effectively. The containerized service simplifies testing and deployment, ensuring compatibility across diverse setups while delivering actionable insights from complex data. Discussions with the NVIDIA team have provided clarity on tailoring the technology to unique production challenges, fostering confidence in its application. By taking these steps, manufacturers have positioned themselves to tackle future uncertainties in semiconductor production, leveraging real-time anomaly detection to safeguard yield and reduce costs. The journey underscores a shift toward proactive, data-driven strategies, setting a precedent for how advanced tools can transform operational landscapes. As the industry continues to evolve, such innovations stand as a testament to the power of targeted technology in overcoming entrenched challenges, paving the way for sustained progress.