While retailers process thousands of orders every single day, most find themselves unable to answer fundamental questions about their own operations, such as identifying the precise reason why a significant percentage of deliveries missed their promised windows on a specific day. The challenge lies not in the collection of data—as every order generates a wealth of timestamps, routes, carrier assignments, and delivery outcomes—but in the critical process of transforming this raw data into actionable decisions. Research has shown that integrating AI into operations can slash inventory by up to 30%, reduce logistics costs by as much as 20%, and cut procurement spending by 15%. Despite these potential gains, a striking 52% of companies continue to manage their order fulfillment through manual or mostly manual processes, a figure that has unfortunately increased from 43% in the preceding year. This growing disconnect highlights a fundamental gap: organizations are logging more orders than ever before but lack the sophisticated systems needed to translate that order data into genuine operational intelligence. The chasm between simply recording orders and actively orchestrating them is what separates businesses that constantly react to problems from those that proactively prevent them, ultimately determining their ability to deliver a consistent, reliable customer experience.

1. The Limitations of Traditional Order Management Systems

Most contemporary order management systems (OMSs) excel at performing the foundational tasks they were designed for, such as capturing orders from various channels, verifying inventory availability, routing orders to appropriate fulfillment nodes, and tracking status updates for customer visibility. However, their capabilities often stop there, leaving a significant intelligence gap. These systems are not equipped to predict capacity stress before it cripples a distribution center during a peak period. They cannot dynamically recommend the most optimal fulfillment node when real-time constraints—such as sudden traffic congestion, shifting dock schedules, or fluctuating carrier availability—emerge. Consequently, critical patterns in late deliveries or consistent cost overruns remain buried deep within vast datasets, never surfacing as actionable insights. Order data is rarely connected to external variables like carrier performance metrics, weather disruptions, or the root causes of delivery failures. A crucial learning loop, where the system would adapt its future recommendations based on the input and overrides from human planners, is conspicuously absent, making the entire operation static and unable to evolve.

This operational blindness is an expensive liability that forces teams into a perpetual state of reactive firefighting rather than proactive orchestration. Planners and logistics managers can clearly see that an order is late, but the system provides no context as to why the delay occurred or what strategic adjustments could prevent a recurrence. It is incapable of distinguishing whether the failure stemmed from a flawed initial plan, a specific carrier’s underperformance on a particular lane, or an unforeseen capacity constraint at a fulfillment center. This lack of diagnostic capability turns daily operations into a series of urgent, disconnected responses to crises. It is no surprise that one recent survey found that 58% of companies are now prioritizing the improvement of order accuracy. This focus would not be necessary if their current systems were delivering the intelligence required to get it right the first time. The next evolution of logistics technology will undoubtedly be defined by its ability to merge pristine data accuracy with advanced decision intelligence, creating systems that function as collaborative partners that think with planners, not just execute tasks for them.

2. The Inevitable Shift to Automation

In today’s competitive retail landscape, the expectation of same-day delivery has rapidly shifted from a premium service to a baseline requirement for many consumers. This new standard has rendered traditional manual planning methods largely obsolete, as they simply cannot scale to manage the complexities of modern fulfillment networks that span multiple nodes and contend with highly volatile daily order volumes. The strain on these outdated processes is evident, with a recent study reporting that 67% of companies are actively seeking ways to achieve better warehouse capacity utilization. This industry-wide push toward efficiency is underscored by Gartner’s prediction that by 2029, a significant number of companies will have transitioned to using 100% automated systems across their logistics, production, and distribution functions. The move toward automation is no longer a question of “if” but “when,” as businesses recognize that it is the only viable path to handling intelligent order routing, dynamic capacity balancing, and automated rerouting in response to delays while remaining competitive.

However, for automation to be truly effective, it must be sophisticated enough to process a multitude of real-world constraints, not just follow a rigid set of pre-programmed rules. A genuinely useful automated system must account for dynamic variables such as dock cut-off times, carrier pickup schedules, customer delivery windows, specific SKU handling requirements, live traffic conditions, and impending weather events. The purpose of this true automation is not to remove humans from the operational loop but rather to augment their capabilities. It equips them with real-time, data-driven recommendations that have already been shaped and validated by these real-world constraints. When implemented correctly, this level of automation fundamentally transforms how operations teams work. Instead of conducting a post-mortem analysis asking, “Why were we late?” after a delivery has already failed, they are presented with a proactive alert: “This route will be late unless we adjust now.” This empowers them to resolve the issue before it ever becomes a problem for the customer, shifting the entire operational paradigm from reactive to preemptive.

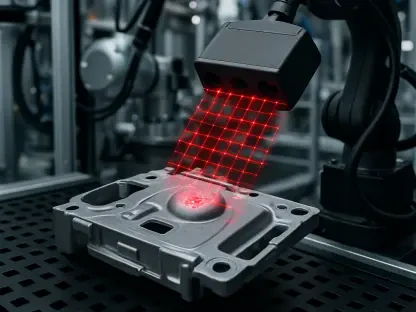

3. Unlocking Predictive Intelligence From Data

The vast amounts of order data collected by businesses hold the key to profound operational insights, but only if the system is architected to extract that intelligence effectively. When it is, the transformation is immediate and far-reaching. Operations teams can begin to identify which fulfillment nodes are consistently the most cost-effective for specific regions or product types, which carriers and routes demonstrate the best on-time delivery success rates, and where customer demand is clustering geographically. More importantly, they can perform deep-dive analyses to understand precisely why certain deliveries fail, moving beyond surface-level symptoms to address root causes. This shift enables a cascade of strategic improvements. Teams can proactively move inventory to forward-stocking locations just before a predicted demand spike instead of scrambling to fulfill orders after the surge has already begun. They can select carriers based on comprehensive performance data rather than relying solely on cost, and they can even implement a delivery-linked checkout process that only promises customers what can realistically be delivered on time.

This is the foundational intelligence that makes a seamless omnichannel retail experience work at scale. Artificial intelligence is the engine driving this capability, simultaneously processing more than 180 distinct variables in real time. Complex factors such as dock schedules, live traffic patterns, carrier availability, vehicle capacity, and promised delivery windows are all factored into every recommendation the system generates. The workflow evolves into an “agentic” model, where AI performs the heavy lifting of complex data analysis to recommend an optimal course of action, and human planners provide the final approval and strategic oversight. This symbiotic relationship ensures that automation handles the overwhelming complexity while people remain in control, steering the ultimate outcomes. Over time, the system grows progressively smarter through continuous learning, adapting to new patterns and planner feedback. As a result, planning cycles that once consumed hours are compressed into mere minutes, and on-time delivery rates begin to approach 100%. This is the powerful outcome when order data ceases to be a passive record of what went wrong and becomes an active, intelligent tool for making better decisions.

4. A Practical Guide to Implementation

One of the most common reasons that ambitious automation projects fail is the attempt to do too much at once, leading to overwhelming complexity and a lack of measurable progress. The implementation approach that consistently yields success is one that starts small, proves its value, and scales based on that proof. The first step in this methodical process is to begin with the highest-pain fulfillment nodes. An organization should identify the specific locations or operational areas where manual planning breaks down most frequently, especially during peak demand periods, when dealing with complex multi-stop routing, or in zones with historically high delivery failure rates. By targeting the most significant bottleneck first, the potential for a high-impact, visible win is maximized. Once this initial area is identified, the next step is to launch a pilot program with a controlled and limited volume of orders. This creates a direct, side-by-side comparison, allowing the new automated system to be tested against the existing manual or semi-manual process. This approach provides a clear and undeniable measurement of the difference in performance, efficiency, and accuracy, laying a data-backed foundation for future expansion.

Building on that foundation requires a disciplined, evidence-based strategy. Before the pilot even begins, it is crucial to establish clear and unambiguous success metrics. These should be concrete proof points that directly reflect business value, such as the reduction in time spent on planning, the percentage improvement in on-time delivery rates, or the decrease in the average cost per order. With these key performance indicators in place, the decision to scale is no longer based on arbitrary timelines or executive pressure but on measurable outcomes. New fulfillment nodes and higher order volumes should only be added to the system as it definitively proves its return on investment at each preceding stage. Finally, the human element of this transformation cannot be overlooked. Building internal adoption must be a gradual process centered on earning trust. Operators and planners need to have confidence in the AI-driven recommendations before they will consistently act on them. This trust is not built through mandates or directives; it is cultivated over time through demonstrated, repeatable results that make their jobs easier and more effective. The ultimate goal is not to automate everything overnight but to begin where the impact is highest, prove the system works, and scale intelligently from there.

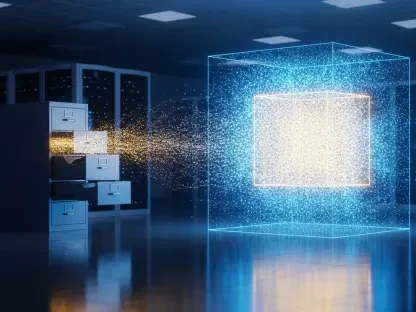

Forging a Proactive Future

The journey from reactive problem-solving to proactive supply chain orchestration was one of fundamental transformation. For years, the order data had existed within the company’s operations, but it had primarily been used as a tool for explaining what had already gone wrong. Systems that only tracked historical events kept teams in a constant state of firefighting, making it nearly impossible to deliver a consistently excellent experience across all sales channels. The implementation of systems designed to surface intelligence and recommend preemptive actions allowed the entire operation to get ahead of problems before they could erode revenue or damage customer trust. The change was not about acquiring new data but about finally unlocking the predictive power within the information that was already being collected. This shift enabled the organization to move from being managed by its supply chain to actively managing it with foresight and precision.