In today’s fast-paced industrial landscape, businesses grapple with an overwhelming volume of data generated by complex operations, often leading to inefficiencies that cost millions annually. Imagine a global manufacturer unable to pinpoint why delivery delays persist despite robust systems in place, highlighting a pressing need for tools that not only uncover hidden bottlenecks but also transform raw data into actionable strategies. Process intelligence platforms have emerged as a pivotal solution, promising to revolutionize how industries like manufacturing and supply chain management navigate operational challenges through advanced analytics and real-time insights.

The significance of these platforms lies in their ability to integrate process mining, artificial intelligence, and data connectivity into a cohesive framework. Designed to optimize business operations, they address the critical demand for visibility and efficiency in an era dominated by digital transformation. This review delves into the core functionalities, recent advancements, and real-world impact of these technologies, shedding light on their role in reshaping operational landscapes across diverse sectors.

Unpacking the Core Features and Performance

Harnessing Process Mining and Digital Twin Capabilities

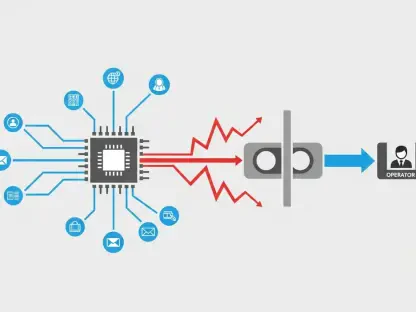

At the heart of process intelligence platforms is process mining, a technology that dissects event logs and data streams to construct a real-time, detailed map of business operations. By sifting through vast amounts of transactional data, these tools reveal the actual flow of processes, often uncovering discrepancies between intended and real-world execution. This granular visibility is essential for identifying inefficiencies, such as redundant steps or delays, that might otherwise remain hidden in traditional reporting methods.

Complementing process mining is the concept of a digital twin, a virtual replica of physical processes that centralizes data into an actionable format. This technology enables organizations to simulate scenarios, test potential improvements, and monitor outcomes without disrupting live operations. The synergy of process mining and digital twins empowers companies to tackle bottlenecks proactively, ensuring smoother workflows and enhanced productivity across departments.

Leveraging AI for Insights and Automation

Artificial intelligence stands as a cornerstone of modern process intelligence platforms, infusing them with predictive analytics and decision-support tools. These AI-driven features anticipate potential disruptions, such as supply chain shortages, by analyzing historical patterns and current trends, thus enabling preemptive action. Such capabilities transform raw data into strategic foresight, equipping businesses with the means to stay ahead of operational challenges.

Beyond prediction, automation features like action flows and process orchestration streamline repetitive tasks, significantly reducing manual workload. For instance, automated workflows can handle routine approvals or inventory adjustments, freeing up staff to focus on higher-value activities. The integration of AI also democratizes data access, providing user-friendly interfaces that allow non-technical employees to make informed decisions swiftly, thereby fostering a culture of agility and responsiveness.

Tracking Innovations and Industry Trends

Recent advancements in process intelligence have introduced groundbreaking approaches like Object-Centric Process Mining (OCPM), which offers a holistic, end-to-end perspective of operations by linking disparate processes into a unified view. Unlike traditional methods that focus on isolated workflows, OCPM connects objects—such as orders or inventory items—across systems, providing deeper insights into interdependencies. This innovation marks a significant leap toward comprehensive transparency in complex environments.

Another notable trend is the shift of digitalization responsibilities from IT departments to business units, ensuring that technology aligns closely with operational needs. This transition reflects a growing emphasis on practical application over purely technical implementation. Additionally, the industry is witnessing a surge in demand for real-time data visibility and system interconnectivity, pushing vendors to enhance platforms with seamless integration capabilities that bridge fragmented data sources.

Real-World Impact Through Case Studies

The practical value of process intelligence platforms shines through in their application across industries, particularly in manufacturing and supply chain management. A standout example is ThyssenKrupp Rasselstein, a leading packaging steel manufacturer based in Germany, which adopted the Celonis platform to overhaul its supply chain operations. Facing intense cost pressures, the company leveraged this technology to address visibility gaps and optimize over 50 use cases spanning processes like procure-to-pay and inventory management.

By creating a digital twin of its supply chain, ThyssenKrupp Rasselstein gained real-time insights into material flows, enabling proactive risk mitigation and improved delivery reliability. The platform’s AI tools, such as Process Copilot, further empowered employees to make data-driven decisions effortlessly, while automation features reduced waste by facilitating surplus inventory sales. Financially, the initiative saved tens of millions of euros in working capital, demonstrating the tangible benefits of embracing such advanced systems.

Addressing Challenges and Barriers

Despite their potential, process intelligence platforms face significant hurdles, particularly in integrating data from disparate, often legacy systems into a unified framework. This technical complexity can delay implementation, as organizations must reconcile varying data formats and protocols. Overcoming this requires robust middleware solutions and standardized data practices, which remain a work in progress for many vendors and adopters alike.

Adoption barriers extend beyond technology to include cultural and skill-related challenges within organizations. Employees often need extensive training to utilize these platforms effectively, while resistance to change can slow deployment. To counter these issues, ongoing efforts focus on enhancing platform usability through intuitive designs and scalable architectures, ensuring broader accessibility and smoother transitions for companies of all sizes.

Envisioning the Path Ahead

Looking toward the future, process intelligence platforms are poised for deeper integration with emerging technologies like advanced AI and the Internet of Things (IoT). Such convergence could enable even more precise monitoring and automation, as IoT devices feed real-time sensor data into process models for instantaneous analysis. This synergy promises to elevate operational resilience, particularly in dynamic industries facing constant flux.

Potential breakthroughs, such as the widespread adoption of OCPM, could redefine transparency by linking every facet of an organization’s processes into a single, coherent view. Over the long term, these platforms are likely to become indispensable for maintaining cost efficiency and securing competitive advantage, as they evolve to address increasingly intricate operational demands across global markets.

Reflecting on a Transformative Journey

Looking back, the exploration of process intelligence platforms revealed their profound capacity to reshape business operations through meticulous data analysis and automation. Their ability to turn fragmented information into strategic assets stood out as a game-changer for industries navigating complex challenges. The success of implementations like ThyssenKrupp Rasselstein’s with Celonis underscored the measurable impact on efficiency and financial performance.

As a next step, organizations should prioritize building internal expertise and fostering a culture receptive to technological change to maximize the benefits of these tools. Collaborating with platform providers to tailor solutions to specific industry needs could further enhance outcomes. Moving forward, staying attuned to innovations like OCPM and IoT integration will be crucial for sustaining momentum and achieving long-term operational excellence.