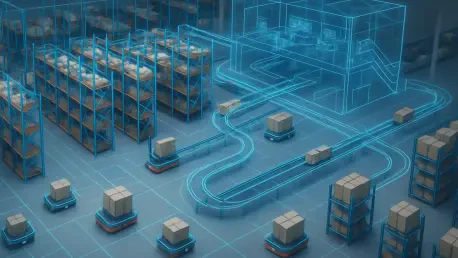

Chloe Maraina has made a name for herself as a Business Intelligence expert who excels at using big data to create impactful visual narratives. Her insights into the integration of data-driven technologies within the industrial landscape provide a unique vantage point into the benefits and future of digital manufacturing. In this interview, she shares her expertise on Siemens’ groundbreaking investment in a fully automated warehouse at their electric motor plant, highlighting its potential to revolutionize productivity and intralogistics through advanced technologies like the digital twin.

What prompted Siemens to invest in building a fully automated warehouse at the electric motor plant in Bad Neustadt?

Siemens recognized the need to modernize their supply chain to keep pace with Industry 4.0 advancements. Investing in a fully automated warehouse was a strategic decision to boost productivity by 40 percent and ensure just-in-time supply to their production cycle. The electric motor plant in Bad Neustadt, which has been pivotal to Siemens since 1937, stands as an ideal site to pioneer this innovative approach and highlight the integration of automation with traditional manufacturing practices.

Could you elaborate on how the new warehouse aims to increase productivity by 40 percent?

The increase in productivity is primarily driven by the warehouse’s automation and innovative logistics system. By implementing cutting-edge technology, Siemens can significantly reduce manual interventions and increase efficiency. Materials are delivered just-in-time, minimizing delays and improving the overall workflow. This streamlined approach notably enhances the speed and accuracy of production processes, achieving a substantial productivity boost.

What specific aspects of Siemens technology were used in the planning and implementation of the warehouse project?

Siemens utilized a variety of its proprietary technologies throughout the warehouse’s development. These included the creation of a digital twin to simulate and optimize warehouse functions, as well as automation components and electric motors for the storage and retrieval systems. This in-house expertise allowed Siemens to seamlessly integrate these components and maintain high standards of efficiency and reliability in the project.

How does the concept of a digital twin contribute to optimizing warehouse operations?

The digital twin acts as a virtual replica of the physical warehouse, enabling advanced simulations and testing before actual implementation. This foresight allows for the optimization of material flow and production processes, identifying potential bottlenecks or inefficiencies early on. By ironing out these issues in the digital realm, Siemens ensures the most effective and streamlined operations in the physical warehouse.

Can you explain the benefits of a digital twin in terms of cost savings and planning reliability?

Creating a digital twin offers significant cost benefits by reducing the risk of planning errors and minimizing unexpected changes during construction. It enhances planning reliability as modifications can be made in the virtual model rather than in the costly physical infrastructure. Furthermore, it accelerates the commissioning process, as solutions are preemptively identified and refined, leading to smoother transitions and quicker project completion.

How does the digital twin enable data-based decision making in the warehouse?

The digital twin allows Siemens to analyze data and make informed decisions about storage strategies and production sequences. By predicting the outcomes of different scenarios, they can choose the most effective methods for integrating supplies and improving sequence efficiency. This database approach ensures agility and precision in responding to both expected and unforeseen events, optimizing the entire intralogistics operation.

What role does the digital twin play in strategic planning for intralogistics?

In strategic planning, the digital twin emerges as a powerful tool that guides long-term logistics strategies, focusing on efficiency and flexibility. It helps model various logistical scenarios, comparing their outcomes, and selecting the most promising ones to implement. This strategic advantage positions Siemens to better adapt to market fluctuations and enhance their overall supply chain resilience.

Can you describe the “goods to people” principle and how it differs from the traditional “people to goods” approach?

The “goods to people” principle transforms traditional warehouse operations by bringing materials directly to the operator, rather than having the operator seek them out. This shift not only accelerates the picking process but also significantly reduces error rates — an improvement reflected in Siemens’ operations, where error rates have reduced by 99 percent. It embodies a level of automation that elevates both speed and efficiency, setting a new standard for warehousing practices.

How does the warehouse serve as a decoupling buffer between prefabrication and order-specific assembly?

The warehouse acts as a critical intermediary that balances the flow between the initial prefabrication of components and their integration into assembly lines. By serving as a buffer, it absorbs fluctuations in demand, ensuring a steady and reliable supply of components for final assembly. This decoupling ensures that any disruption doesn’t ripple into the production, preserving the continuity and responsiveness of Siemens’ operations.

Could you explain the impact of the warehouse on flexibility and responsiveness in production processes?

The warehouse’s design inherently enhances flexibility by allowing Siemens to adjust production schedules swiftly in response to market demands or disruptions. Its buffering capability enables the maintenance of optimal stock levels, promoting rapid responses to changes without compromising on assembly timelines. This adaptability boosts the plant’s overall efficiency and ability to meet evolving business needs.

What measures have been implemented to ensure that fluctuations in demand or disruptions don’t affect final assembly?

To mitigate the impact of demand fluctuations or potential disruptions, Siemens has established a robust buffering system in the warehouse. The decoupling of fabrication from assembly means that any upstream delays aren’t directly felt in the final production stages. This proactive approach ensures that final assembly lines remain operational and unaffected by temporary supply chain variances.

How does the fast-picking zone with 21 picking ports contribute to just-in-time supply in the production cycle?

The fast-picking zone is a pivotal feature that enhances the just-in-time principle by ensuring timely delivery of parts. With 21 picking ports, it facilitates rapid retrieval and dispatch, meeting assembly line demands precisely when needed. This capability maximizes throughput and reduces waiting times, aligning production closely with the immediate demands of the manufacturing cycle.

What are the expected throughput times and capabilities of the warehouse in terms of pallets and transport containers?

The warehouse operates with remarkable efficiency, moving around 3,100 pallets and more than 3,800 transport containers daily across three shifts. This high throughput capacity ensures that materials circulate swiftly, effectively supporting the fast-paced production environment and maintaining optimal stock levels to meet fluctuating demands with agility.

How has the error rate during order picking been reduced by 99 percent?

The dramatic reduction in error rate is largely attributable to the implementation of the “goods to people” principle and advanced automation technologies. These innovations minimize human error by significantly lowering the complexity and manual processes involved in picking, thus ensuring a highly accurate and efficient workflow.

What impact does the new warehouse system have on material circulation within the plant?

The new system significantly streamlines material circulation, reducing unnecessary movements and optimizing the flow of inventory through the plant. This efficiency contributes to a 40 percent reduction in material circulation, resulting in lower operational costs, faster production times, and a more organized and manageable flow of goods throughout the facility.

Would you consider this warehouse as a model for future industry standards, and if so, why?

Siemens’ warehouse undoubtedly sets a benchmark for future standards in industry. Its integration of digital twins, cutting-edge automation, and strategic logistical innovations present a comprehensive blueprint for modern manufacturing systems. These advancements point the way forward for companies seeking to enhance productivity, reduce errors, and create more resilient supply chains.

What is your forecast for the future of digital automation in manufacturing?

The trajectory of digital automation in manufacturing is promising, with ongoing developments in AI, machine learning, and IoT set to further transform the industry. These technologies will continue to enhance process efficiencies, reduce costs, and allow for greater customization and responsiveness. I foresee an era where real-time data-driven insights shape decision-making processes, pushing the boundaries of what traditional manufacturing can achieve.