What happens when the manufacturing floor, the heartbeat of industrial progress, grinds to a halt under the weight of unrelenting disruptions? Geopolitical tensions snarl supply chains, climate crises shutter plants, and a shrinking pool of skilled workers leaves critical tasks undone. Yet, amid this chaos, a powerful alliance between Generative Artificial Intelligence (GenAI) and Operational Technology (OT) offers a transformative solution. This fusion promises not just to weather the storm but to rebuild manufacturing into a fortress of resilience, turning data and expertise into actionable strength.

Why the Fight for Resilience Is Urgent

The manufacturing sector stands at a critical crossroads. External shocks, from trade disputes to extreme weather, disrupt operations with alarming frequency, while internal challenges like aging workforces and rising equipment complexity compound the strain. These issues aren’t mere inconveniences—they threaten safety, erode profits, and stall growth. The urgency to adapt has never been clearer, as traditional approaches to digital transformation struggle to convert raw data into real-world solutions.

Resilience in this context means more than survival; it’s about creating systems that anticipate, respond, and recover from disruptions with minimal impact. The integration of GenAI with OT emerges as a pivotal strategy, offering tools to bridge gaps that have long plagued the industry. This isn’t just a technological fix—it’s a fundamental shift in how plants operate under pressure.

Decoding the GenAI and OT Partnership

At the core of this revolution lies the synergy between OT, the foundation of plant operations, and GenAI, a cutting-edge force in intelligent reasoning. OT encompasses the nuts and bolts of manufacturing—startups, shutdowns, inspections, and troubleshooting—while generating critical data like equipment logs and diagnostic skills honed by seasoned operators. GenAI elevates this by not merely accessing data but analyzing it through advanced frameworks like retrieval-augmented reasoning, which maps equipment relationships and pinpoints failures with precision.

This partnership goes beyond older AI models that falter in novel scenarios. GenAI’s ability to reason through interconnected systems ensures evidence-based actions, even for undocumented issues. A striking example comes from a trial with a major air conditioning equipment manufacturer, where an AI agent achieved over 90% diagnostic accuracy for unseen failures, slashing response times to a mere 10 seconds. Such results underscore the potential to transform chaos into control on the plant floor.

The impact is tangible: reduced mean time to repair (MTTR), standardized maintenance across sites, and a buffer against labor shortages. This duo doesn’t just react to problems—it anticipates them, offering a proactive shield against the unpredictable.

Real-World Voices and Hard Evidence

Insights from industry leaders paint a vivid picture of this technology’s value. Experts with deep roots in industrial tech emphasize that GenAI’s strength lies in “capturing and scaling the know-how of veteran operators,” ensuring consistency regardless of who’s on shift. In the trial mentioned earlier, the AI agent not only matched but often surpassed the diagnostic prowess of experienced engineers, a critical advantage for companies expanding amid workforce constraints.

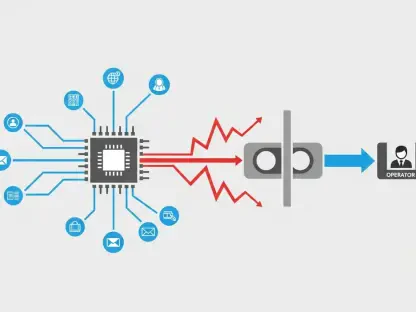

Data further validates this shift. Research highlights that traditional AI methods, such as retrieval-augmented generation (RAG), often stumble in high-stakes settings, unable to adapt to unique failures. In contrast, reasoning-based systems excel, delivering precise solutions where others fail. These findings, coupled with real trial outcomes, position GenAI and OT as essential tools for navigating today’s manufacturing challenges.

Testimonials from the field add another layer of credibility. Plant managers involved in early deployments note that the speed and accuracy of AI-driven diagnostics have fundamentally changed how they approach downtime, turning hours of guesswork into seconds of clarity. This convergence of expert opinion and empirical results builds a compelling case for widespread adoption.

Practical Steps to Build Unshakable Operations

How can manufacturers harness this potential? A starting point is integrating OT data—think equipment diagrams and historical records—into knowledge graphs that GenAI can navigate, laying the groundwork for intelligent troubleshooting. This structured approach ensures that critical information isn’t buried in silos but is readily actionable.

Another key step involves adopting retrieval-augmented reasoning frameworks to move past static data retrieval. This enables AI to propose tailored solutions for complex, one-off failures, enhancing both speed and safety. Partnering with technology providers to customize AI agents for specific plant needs can further amplify impact, focusing on rapid diagnostics and error reduction.

Finally, leveraging these tools to codify the expertise of seasoned staff addresses the skills gap head-on. By embedding best practices into AI systems, manufacturers can ensure uniform performance across teams and locations. These strategies collectively pave the way for operations that not only survive disruptions but thrive in spite of them, minimizing downtime and bolstering workplace safety.

Looking Ahead After Transformative Strides

Reflecting on the journey, the alliance of GenAI and OT has proven itself a game-changer for an industry battered by relentless challenges. The path forward became clearer with each successful trial, as diagnostic accuracy soared and repair times plummeted. Manufacturers who embraced this technology found themselves not just reacting to crises but outpacing them, armed with tools that scaled human expertise to unprecedented levels.

As the industry moved into the next phase, the focus shifted to broader implementation, ensuring that small and mid-sized plants could also access these innovations. Exploring ways to integrate predictive capabilities offered another frontier, promising to stop disruptions before they even started. The momentum built in those early adoptions laid a foundation for a future where manufacturing resilience was no longer an aspiration but a standard, achieved through the seamless blend of human insight and intelligent systems.