The manufacturing sector is confronting a daunting challenge: a growing shortage of skilled labor. With the Manufacturing Institute predicting a potential shortfall of up to four million employees by 2030, manufacturers are compelled to seek innovative solutions to sustain productivity and efficiency. Amid this pressing scenario, the adoption of digital technologies, particularly Artificial Intelligence (AI) and cloud-based systems, emerges as a beacon of hope. These cutting-edge technologies promise to revolutionize the manufacturing landscape, ensuring continuous operation despite the prevalent labor deficiencies.

The Role of AI in Addressing Labor Shortages

Artificial Intelligence is increasingly seen as a pivotal tool in tackling labor shortages in the manufacturing sector due to its ability to automate repetitive tasks and optimize production processes. By deploying AI-driven robotics, manufacturers can alleviate the burden on human workers, allowing them to engage in more complex, value-adding activities. This not only boosts productivity but also enhances safety within manufacturing environments by minimizing human exposure to potentially hazardous tasks.

Predictive maintenance stands out as another significant benefit of AI, further alleviating the impact of labor shortages. By leveraging AI to predict equipment failures, manufacturers can undertake proactive maintenance measures, thereby reducing costly downtimes and repair expenses. This foresight ensures that machinery operates at peak efficiency, compensating for the reduced availability of skilled labor and maintaining seamless manufacturing operations.

Moreover, AI has a crucial role in refining production quality and control. Through the analysis of vast data sets, AI systems can identify patterns and anomalies that might elude human observation, leading to more consistent product quality and fewer defects. This not only enhances efficiency but also minimizes waste, contributing to the overall profitability of manufacturing operations. By adopting AI, manufacturers can effectively counterbalance labor shortages while driving innovation and excellence in production.

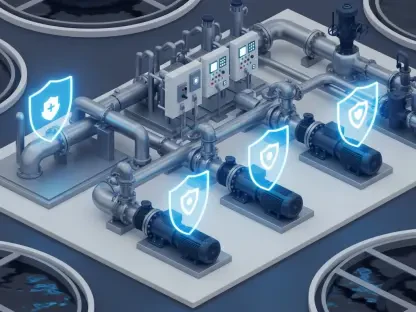

Cybersecurity Challenges in the Digital Age

While the integration of AI and digital tools offers considerable advantages, it concurrently introduces new cybersecurity vulnerabilities that manufacturers must address. The substantial amounts of data generated by AI-driven initiatives render manufacturing enterprises prime targets for cybercriminals. In 2023, nearly a quarter of all cyber-attacks globally were directed at manufacturing companies, underscoring the sector’s susceptibility and resulting in significant financial damages.

Traditional cybersecurity protocols have proven insufficient in countering these advanced threats, necessitating a proactive approach to data protection. Manufacturers must implement robust cybersecurity measures to shield their data assets, ensuring the ongoing integrity and security of their operations. Failure to do so could leave them vulnerable to catastrophic cyber-attacks, with dire repercussions for their business continuity and financial health.

Adopting a proactive cybersecurity stance involves leveraging advanced tools and strategies tailored to the evolving threat landscape. This includes continuous monitoring and real-time threat detection to promptly address potential breaches. Additionally, manufacturers should prioritize regular updates and patches to their systems to mitigate emerging vulnerabilities. By staying ahead of cyber threats through diligent safeguards, manufacturers can protect their valuable data assets and sustain their operations in an increasingly digital-driven world.

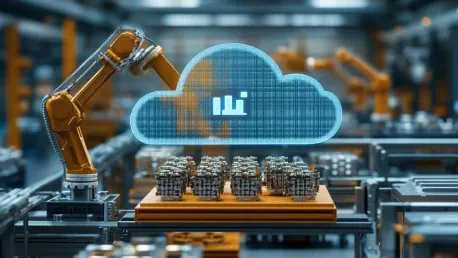

Embracing Cloud-Based Solutions

In response to the accelerated demand for digitalization and enhanced operational efficiency, many manufacturing enterprises are turning to cloud-based Enterprise Resource Planning (ERP) technologies. These cloud-centric systems streamline processes, boost visibility into operations, and support automation initiatives, all while offering sophisticated cybersecurity tools. Through centralized data management, role-based access control, data encryption, and comprehensive monitoring tools, cloud-based ERPs provide a robust framework to protect sensitive business data.

The benefits of cloud-based ERPs extend beyond robust security measures to include continuous monitoring and real-time threat detection. These systems are designed to address evolving cyber risks through automatic updates and adherence to stringent compliance standards, ensuring that business data remains safeguarded. The scalability of cloud platforms is another crucial advantage, enabling organizations to adapt seamlessly to new threats and regulatory changes without the need for extensive infrastructure overhauls.

Cloud-based ERPs provide manufacturers with a resilient and flexible foundation to enhance their operations. By integrating these advanced systems, manufacturers can streamline their processes, improve productivity, and protect their data integrity in a rapidly changing digital landscape. This proactive adoption of cloud technologies not only addresses current vulnerabilities but also positions manufacturers for future growth and innovation.

Best Practices for Data Security

Beyond the adoption of cloud technologies, additional best practices are essential for manufacturers to effectively secure their data and systems. One critical aspect involves controlling digital access and educating employees about cybersecurity risks. Studies reveal that a significant percentage of data breaches can be attributed to human error. Comprehensive cybersecurity education programs can empower employees to recognize and counter common attack vectors such as phishing scams.

Investing in next-generation endpoint protection solutions with advanced threat detection capabilities is equally paramount. Managed services that offer round-the-clock monitoring provide an added layer of defense against emerging cyber threats, especially beneficial for small and medium-sized enterprises (SMEs) that may lack dedicated cybersecurity expertise. Cloud-based ERP systems also reinforce data security by ensuring that employees access only data pertinent to their roles, thereby mitigating insider threats and limiting exposure to sensitive information.

By adhering to these best practices, manufacturers can create a resilient security framework that safeguards their digital assets. This multifaceted approach encompasses technology adoption, employee training, and strategic investments in security infrastructure, collectively fortifying the organization’s defense against cyber threats. Implementing robust data security measures is not only a necessity but also a strategic imperative in today’s digitally driven manufacturing landscape.

Backup Strategies and Vendor Management

The manufacturing sector is facing a significant challenge: a severe shortage of skilled labor. According to the Manufacturing Institute, there could be a shortfall of up to four million employees by 2030. This shortage forces manufacturers to look for innovative solutions to maintain productivity and efficiency. In response to this pressing issue, the adoption of digital technologies, especially Artificial Intelligence (AI) and cloud-based systems, offers a promising solution. These advanced technologies are set to revolutionize the manufacturing industry, ensuring continuous and efficient operations despite the ongoing labor shortages. AI can automate various tasks, reducing the dependence on human labor while increasing precision and speed in manufacturing processes. Cloud-based systems enhance collaboration, streamline operations, and provide real-time data, allowing manufacturers to make more informed decisions. By integrating these technologies, manufacturers can not only address the immediate labor crisis but also build a more resilient and forward-thinking industry for the future.