In a landscape where national security increasingly hinges on technological superiority, a groundbreaking partnership between two industry giants signals a transformative shift in defense manufacturing. Boeing Defense, a cornerstone of the U.S. defense sector, has joined forces with Palantir Technologies to integrate cutting-edge AI solutions into its operations. Announced at a prominent defense industry event, this collaboration aims to revolutionize how data is managed and utilized in the production of military aircraft, spacecraft, and weapons systems. By leveraging Palantir’s Foundry AI software, Boeing seeks to enhance efficiency, improve quality control, and maintain stringent security for classified programs. This alliance not only addresses the pressing need for agility in response to geopolitical challenges but also sets a new standard for innovation in the defense realm. As global tensions escalate, the ability to deliver advanced systems swiftly becomes paramount, and this partnership positions Boeing at the forefront of that mission.

Harnessing AI for Manufacturing Excellence

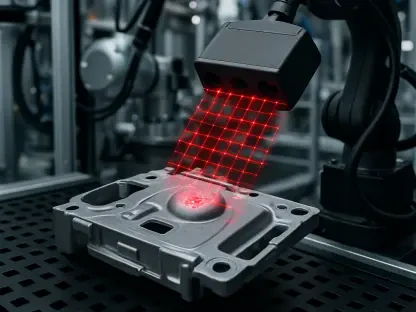

The core of this collaboration lies in transforming Boeing’s manufacturing processes through the integration of Palantir’s Foundry platform, a powerful tool designed to unify disparate data sources. This AI-driven software pulls information from product lifecycle management, manufacturing execution systems, and logistics databases to create a cohesive framework for real-time analytics. The primary goal is to establish a shared data structure, often referred to as an ontology, which allows seamless communication across various systems. Such integration enables Boeing to monitor production tolerances and supplier performance with unprecedented precision. By catching minor discrepancies early, the system helps prevent larger issues that could lead to delays or cost overruns. In an industry where every minute counts, especially for military projects, this capability ensures that production timelines for critical systems like fighter jets and satellites remain on track, bolstering operational readiness in an unpredictable global environment.

Beyond just tracking data, the partnership focuses on actionable insights that directly impact manufacturing outcomes. Foundry’s advanced analytics provide Boeing with the ability to predict potential bottlenecks and optimize workflows in real time, minimizing waste and enhancing efficiency. For instance, by aligning data from testing equipment with quality metrics, engineers can swiftly identify and address defects before they escalate into major problems. This proactive approach not only saves resources but also ensures that the final products meet the exacting standards required for defense applications. Additionally, the system’s ability to streamline communication between different departments means that decision-making becomes faster and more informed. As military demands grow increasingly complex, having a robust, data-driven infrastructure becomes essential for maintaining a competitive edge. This initiative reflects a broader industry shift toward embracing digital tools to tackle the intricate challenges of modern defense manufacturing.

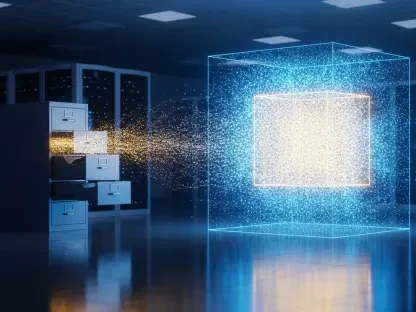

Securing Data in Classified Environments

A critical component of this partnership is ensuring the security of sensitive information, particularly in classified programs where breaches could have severe consequences. Palantir’s Foundry platform incorporates stringent access controls and detailed configuration management to safeguard data while still providing comprehensive visibility to authorized personnel. Program managers and engineers can access real-time updates on project status without risking exposure of confidential details, a balance that is vital in the defense sector. The system’s design allows for secure connectivity across various operational layers, ensuring that even as data is shared and analyzed, it remains protected from unauthorized access. This focus on security is especially relevant given the increasing sophistication of cyber threats targeting defense contractors, making robust protective measures a non-negotiable priority in such collaborations.

Moreover, the integration of AI extends beyond mere data protection to enhance operational efficiency within these secure environments. Foundry’s predictive models play a pivotal role by optimizing repair workflows and improving outcomes for intricate subassemblies critical to military systems. By correlating telemetry data with quality indicators, the platform enables faster detection of potential issues, allowing for preemptive corrections that maintain project integrity. This capability is particularly valuable in classified settings where delays or errors can compromise mission timelines. The emphasis on controlled access also means that only relevant stakeholders receive specific insights, reducing the risk of information overload while maintaining clarity in decision-making processes. As defense projects often operate under intense scrutiny and tight schedules, such innovations ensure that Boeing can uphold its commitments to national security without sacrificing the confidentiality that these programs demand.

Shaping the Future of Defense Technology

This strategic alliance between Boeing and Palantir underscores a pivotal trend in the defense industry toward standardized, data-driven environments that prioritize efficiency and adaptability. Moving away from fragmented systems that once hindered communication, the adoption of a unified data framework facilitates smoother internal processes and strengthens national defense capabilities. In a geopolitical climate marked by rising tensions, governments expect contractors to respond rapidly to evolving needs, a challenge that requires agile manufacturing and reliable supply chains. By embedding AI into its operational core, Boeing not only addresses these expectations but also sets a precedent for how digital transformation can redefine traditional defense manufacturing. This shift is crucial for maintaining a strategic advantage in an era where technological innovation often determines the balance of power on the global stage.

Looking ahead, the implications of this collaboration extend far beyond immediate operational gains, pointing to a future where data and AI are integral to defense readiness. The successful implementation of Foundry’s capabilities in Boeing’s workflows demonstrates a commitment to leveraging technology for enhanced international collaboration and resilience. Reflecting on the strides made, it becomes evident that such partnerships could inspire other contractors to adopt similar approaches, fostering a collective push toward modernization. As the defense sector continues to evolve, the focus shifts to exploring scalable solutions that could further integrate AI across broader applications, ensuring sustained competitiveness. This alliance highlights the importance of viewing data as a strategic asset, a perspective that promises to shape policies and practices for years to come, driving innovation amidst the complexities of global security demands.