In today’s rapidly advancing industrial landscape, small and medium-sized enterprises (SMEs) are finding a powerful ally in Internet of Things (IoT) technologies for equipment monitoring, fundamentally changing how businesses manage their machinery. These cutting-edge tools shift the approach from the traditional, often costly method of addressing failures after they occur to a more strategic, proactive stance. By harnessing real-time data and advanced analytics, IoT solutions enable SMEs to anticipate issues, streamline maintenance processes, and ultimately safeguard their bottom line. This transformation is not just a luxury for larger corporations but a critical opportunity for smaller players to compete on a more level playing field. The ability to monitor equipment health continuously and respond swiftly to potential problems is proving to be a game-changer, especially for industries where downtime can lead to significant financial losses. This article explores how IoT tools are making high-tech maintenance accessible, delving into the specific benefits they offer SMEs, the variety of platforms available, and the challenges that come with adoption. From predictive analytics to mobile-friendly interfaces, these innovations are empowering smaller businesses to operate with the efficiency and foresight once reserved for industry giants.

Transforming Maintenance with Predictive Insights

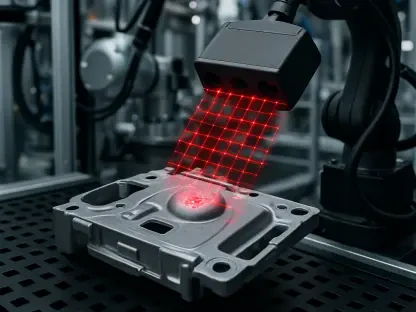

The advent of IoT technologies has ushered in a significant shift for SMEs, moving maintenance practices from reactive fixes to predictive strategies that prevent failures before they disrupt operations. This approach relies heavily on sensor data collected from equipment, which is then analyzed to identify patterns or anomalies that signal potential issues. By forecasting when a machine might fail, businesses can schedule maintenance during planned downtimes, avoiding the chaos and expense of unexpected breakdowns. This predictive capability is a cornerstone of modern IoT tools, offering SMEs a chance to enhance overall equipment effectiveness while minimizing repair costs. The impact is particularly profound in sectors like manufacturing or logistics, where even a few hours of downtime can ripple through supply chains and customer commitments. As a result, adopting predictive maintenance through IoT is becoming less of an option and more of a necessity for smaller firms aiming to maintain a competitive edge in a demanding market.

Several leading platforms are at the forefront of delivering these predictive insights to SMEs, integrating artificial intelligence to refine their capabilities. Solutions such as SAP Asset Performance Management and IBM Maximo Application Suite utilize AI-driven analytics to detect irregularities and estimate the remaining useful life of critical assets. This means that maintenance teams can prioritize their efforts based on data-driven insights rather than guesswork or rigid schedules. For SMEs, this translates into greater control over operational expenses, as resources are allocated only when and where they are truly needed. Additionally, condition-based maintenance, supported by platforms like Microsoft Azure IoT and UpKeep, allows actions to be triggered by the real-time health of equipment rather than arbitrary timelines. This flexibility ensures that smaller businesses, often operating with limited staff and budgets, can maintain high productivity without overextending their resources. The blend of predictive and condition-based approaches is redefining how SMEs approach asset management, making efficiency an achievable goal.

Harnessing Real-Time Data and Edge Computing

A defining feature of IoT tools for equipment monitoring is their ability to provide real-time data, offering SMEs an immediate view into the status of their machinery. This constant stream of information is invaluable, particularly for industries managing remote or dispersed assets where delays in identifying issues can lead to significant losses. Real-time monitoring enables maintenance teams to receive alerts the moment a problem is detected, allowing for swift interventions that prevent minor glitches from escalating into major failures. This capability is especially critical for businesses in sectors like transportation or facility management, where equipment reliability directly impacts service delivery. By keeping a close watch on asset health through IoT dashboards, SMEs can make informed decisions quickly, ensuring operations run smoothly even under challenging conditions. The immediacy of this data transforms reactive responses into proactive management, a vital advantage for smaller enterprises.

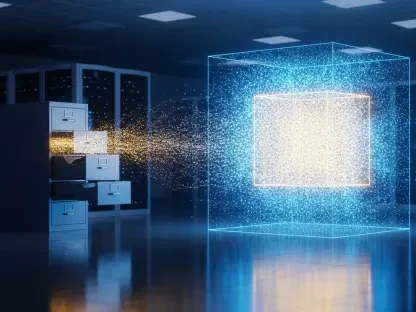

Edge computing further enhances the power of real-time data by processing information directly at the source, minimizing latency and ensuring instant responses even in areas with limited connectivity. Platforms such as AWS IoT and Siemens Insights Hub are leading examples, designed to handle data locally on devices or nearby servers rather than relying solely on distant cloud systems. This approach is particularly beneficial for SMEs with operations in remote locations, where internet reliability may be inconsistent, yet the need for timely alerts remains paramount. Edge computing reduces the risk of data bottlenecks, ensuring that critical notifications reach maintenance teams without delay. For smaller businesses, this technology means that geographical constraints no longer hinder effective equipment monitoring, allowing them to maintain high standards of operational uptime. The synergy of real-time data and edge computing is proving to be a cornerstone of IoT solutions tailored for the unique needs of SMEs.

Accessible Platforms Designed for Smaller Businesses

Recognizing the unique constraints faced by SMEs, many IoT tool developers have crafted solutions that prioritize ease of use and affordability over the complex functionalities often seen in enterprise-grade systems. Platforms like UpKeep, MaintainX, and Limble CMMS are built with smaller operations in mind, featuring intuitive, mobile-first interfaces that don’t require extensive technical expertise to navigate. These tools allow maintenance teams to monitor equipment health, schedule tasks, and track work orders directly from smartphones or tablets, fitting seamlessly into the fast-paced, resource-limited environments typical of SMEs. This focus on accessibility ensures that businesses without dedicated IT departments can still leverage the benefits of IoT, transitioning from outdated manual processes to streamlined, data-driven maintenance. The simplicity of these platforms is a key factor in their growing adoption among smaller firms looking to modernize without overwhelming their staff or budgets.

Beyond user-friendliness, these SME-focused IoT tools often integrate traditional maintenance management systems with innovative IoT triggers, creating a bridge to advanced strategies without requiring a complete overhaul of existing practices. For instance, condition-based maintenance features allow alerts to be generated based on real-time sensor data, ensuring that interventions occur only when necessary. This targeted approach helps SMEs avoid unnecessary expenses while extending the lifespan of their equipment. Although these platforms may lack the sophisticated predictive analytics found in larger suites, their cost-effectiveness and straightforward implementation make them ideal for businesses taking initial steps into IoT adoption. By offering a balance between functionality and simplicity, such tools empower smaller enterprises to enhance operational reliability and compete more effectively in their respective markets, proving that advanced technology need not be out of reach for modest budgets.

Navigating Scalability and Security Concerns

As SMEs grow and their operational needs evolve, the scalability of IoT tools becomes a pivotal consideration in ensuring long-term value from these investments. Platforms like AWS IoT and Microsoft Azure IoT stand out for their ability to adapt to increasing demands, offering customizable setups that can handle larger equipment fleets or more complex data requirements. However, this flexibility often comes with a caveat: the need for technical expertise to configure and maintain these systems. For smaller businesses with limited in-house capabilities, this can pose a significant barrier, potentially requiring external support or additional training. The challenge lies in balancing the desire for a scalable solution with the practical realities of resource availability, ensuring that growth does not outpace the ability to manage the technology effectively. SMEs must carefully assess their current and future needs when selecting IoT tools to avoid being locked into systems that become cumbersome as operations expand.

Security presents another critical concern for SMEs adopting IoT tools, particularly as the number of connected devices multiplies across various locations. The risk of data breaches or unauthorized access to equipment controls can have severe consequences, from operational disruptions to financial losses. Solutions like TELUS IoT Connectivity & Device Management address this by prioritizing secure connections and robust device management protocols, safeguarding sensitive information even in sprawling networks. For smaller enterprises, where dedicated cybersecurity teams are often absent, such built-in protections are essential to maintaining trust in IoT systems. The emphasis on security underscores the importance of choosing platforms that not only deliver monitoring capabilities but also protect the integrity of the data and devices involved. As SMEs integrate more IoT tools into their operations, ensuring a secure foundation will remain a top priority to mitigate risks in an increasingly connected industrial landscape.

Boosting Workforce Productivity with IoT Innovations

IoT tools extend their impact beyond mere equipment monitoring by enhancing the efficiency of the workforce tasked with maintenance responsibilities, a crucial factor for SMEs with limited staff. Platforms like Augmentir Connected Worker Platform focus on digitizing workflows, providing frontline workers with digital instructions and AI-guided troubleshooting directly at the point of need. This approach minimizes guesswork and reduces the time spent resolving issues, enabling teams to address equipment problems more effectively. For smaller businesses, where every employee often wears multiple hats, such tools ensure that maintenance tasks are completed with precision, even by those without extensive technical training. The result is a more agile workforce capable of maintaining high operational standards without the need for constant oversight, a significant advantage in resource-constrained environments.

Integration with existing systems further amplifies the value of these workforce-focused IoT solutions, allowing SMEs to modernize their processes without discarding established practices. By connecting seamlessly with current maintenance or enterprise resource planning systems, these platforms ensure a smooth transition to digital workflows, avoiding the disruption of a full system overhaul. This compatibility is particularly beneficial for smaller firms that may lack the budget or time for extensive retraining or infrastructure changes. The emphasis on supporting workers through accessible technology reflects a broader trend in IoT development: creating tools that not only monitor machines but also empower the people who keep them running. For SMEs, this dual focus on equipment and workforce efficiency offers a practical path to operational improvement, ensuring that limited resources are utilized to their fullest potential in maintaining business continuity.

Paving the Way for Future Success

Reflecting on the journey of IoT adoption among SMEs, it’s evident that these tools have already begun to reshape equipment monitoring by delivering unprecedented insights and control over maintenance processes. Their role in shifting from reactive repairs to predictive and condition-based strategies marks a turning point, allowing smaller businesses to avoid the heavy toll of unexpected downtime. Platforms tailored for SMEs, with their emphasis on simplicity and affordability, have broken down barriers to entry, while more scalable solutions cater to those preparing for growth. Security and workforce efficiency also emerge as vital components, ensuring that the benefits of IoT extend beyond machinery to the broader operational ecosystem. Looking ahead, SMEs are encouraged to evaluate their specific needs—considering factors like technical capacity and budget—when selecting tools, ensuring alignment with long-term goals. Exploring pilot programs or phased implementations could further ease the transition, minimizing risks while maximizing impact. As the landscape of industrial technology continues to evolve, staying informed about emerging IoT advancements will be key to sustaining a competitive advantage, offering SMEs a clear path to build resilience and efficiency in their operations.