Imagine a manufacturing plant where every machine, sensor, and system communicates seamlessly, predicting failures before they occur and optimizing energy use in real time, all while fending off sophisticated cyber threats. This is no longer a distant dream but a reality for industries embracing the convergence of Operational Technology (OT) and the Internet of Things (IoT). This transformative integration is reshaping how factories operate, driving efficiency, and unlocking data-driven insights. Yet, with such connectivity comes heightened risks, especially in cybersecurity. This review dives deep into the features, performance, and challenges of OT and IoT convergence, spotlighting its real-world impact through the lens of PGP Glass, a global glass packaging leader, while exploring its broader implications for the industrial sector.

Understanding the Fusion of OT and IoT

At its core, OT and IoT convergence bridges the gap between traditional industrial control systems and modern networked technologies. OT encompasses hardware and software that manage physical processes, such as machinery in manufacturing plants, while IoT introduces internet-connected devices and sensors for data collection and analysis. This integration enables a unified ecosystem where data from shop floors can inform strategic decisions, fostering smarter operations. The push toward this synergy aligns with Industry 4.0, a movement emphasizing automation and digital transformation in manufacturing environments.

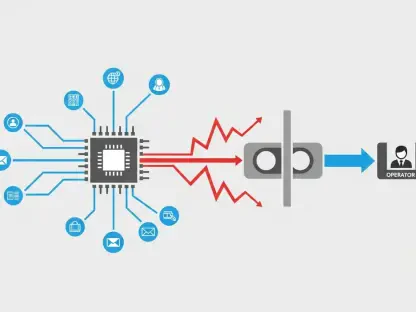

The significance of this trend lies in its ability to address long-standing inefficiencies. Historically, OT systems operated in isolation, disconnected from broader networks, which limited visibility and responsiveness. By integrating IoT, industries gain access to real-time insights, allowing for proactive maintenance and resource optimization. However, this connectivity also exposes vulnerabilities, as systems once shielded by air gaps now face digital threats, making security a pivotal concern in this evolving landscape.

Key Features and Technical Components

IoT Platforms and Real-Time Data Insights

One of the standout features of OT and IoT integration is the deployment of IoT platforms that enable real-time data collection. Sensors embedded in industrial equipment gather critical metrics on performance, energy use, and wear, transmitting this information via gateways to cloud-based systems for analysis. For instance, PGP Glass has implemented 12,000 energy sensors across its facilities, providing granular visibility into consumption patterns and driving annual savings of $2 to $3 million through targeted efficiency measures.

This capability transforms operational monitoring by identifying anomalies instantly, reducing downtime, and enhancing decision-making. IoT platforms often incorporate user-friendly dashboards, allowing plant managers to track key performance indicators without needing deep technical expertise. The scalability of these systems further supports their adoption, as they can expand to accommodate growing numbers of connected devices across multiple locations.

Beyond monitoring, the data collected fuels advanced analytics, enabling predictive maintenance models that anticipate equipment failures. This proactive approach minimizes disruptions and extends asset lifespan, a critical advantage in high-stakes manufacturing settings. The seamless flow of information from ground-level operations to executive oversight exemplifies how IoT amplifies OT’s traditional strengths.

OT Infrastructure and Legacy Challenges

Traditional OT systems, such as Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controllers (PLCs), and Computer Numerical Control (CNC) machines, form the backbone of industrial operations. These technologies excel at controlling physical processes with precision but were designed for isolated environments, lacking inherent security features for networked settings. As a result, integrating them with IoT solutions often reveals compatibility issues, requiring significant retrofitting or middleware to bridge the gap.

The historical isolation of OT infrastructure poses a dual challenge: maintaining reliability while adapting to connectivity demands. Many systems in use today predate modern cybersecurity concerns, making them susceptible to attacks when exposed to external networks. PGP Glass encountered such hurdles during its digital transformation, needing to balance the preservation of core functionalities with the introduction of IoT-driven enhancements.

Moreover, the complexity of managing legacy systems alongside cutting-edge IoT tools demands specialized expertise. Training staff to navigate this hybrid environment is essential, as is ensuring that updates to older systems do not compromise operational stability. These challenges underscore the need for strategic planning in OT and IoT integration projects to avoid costly missteps.

Performance and Industry Applications

The performance of OT and IoT convergence shines in its ability to drive measurable outcomes across diverse industrial applications. In manufacturing, this integration enhances productivity by automating routine tasks and providing actionable insights through data analytics. PGP Glass, for example, leverages IoT to monitor energy usage in near-real time, aligning with sustainability goals by shifting to renewable sources and achieving significant cost reductions.

Beyond efficiency, the technology supports innovative use cases like smart shop floors, where interconnected devices enable dynamic workflow adjustments. This adaptability ensures that production lines can respond swiftly to demand fluctuations or supply chain disruptions. Such agility is particularly valuable in competitive markets where speed and precision dictate success, demonstrating the practical impact of convergence on operational excellence.

The broader industry impact is evident in improved quality control and reduced waste. By embedding IoT sensors into production processes, manufacturers can detect defects early, minimizing rework and ensuring consistent output. These advancements collectively position OT and IoT integration as a cornerstone of modern industrial strategy, delivering both economic and environmental benefits.

Recent Advancements and Emerging Trends

Recent developments in OT and IoT convergence highlight the role of Artificial Intelligence (AI) and Machine Learning (ML) in elevating system capabilities. These technologies enable predictive analytics, allowing firms to foresee operational bottlenecks and optimize processes before issues arise. The incorporation of AI-driven insights is becoming a standard expectation, pushing the boundaries of what automated systems can achieve in industrial settings.

Another notable trend is the increasing focus on IT and OT convergence maturity. Industry surveys, such as those conducted by Omdia, reveal that a growing percentage of manufacturing firms—projected to reach 70% within the next two years—prioritize full integration of these domains. This shift reflects a recognition of the strategic value in unifying data streams to enhance oversight and responsiveness across organizational levels.

Cybersecurity has also emerged as a critical driver of innovation in this space. With manufacturing being a prime target for ransomware and other digital attacks, there is a pressing need for robust protective measures. Solutions like agentless monitoring platforms are gaining traction, offering non-intrusive ways to secure OT environments while maintaining performance, a trend that continues to shape the technology’s evolution.

Challenges in Implementation

Despite its benefits, OT and IoT convergence faces significant hurdles, with cybersecurity risks topping the list. The manufacturing sector is highly vulnerable, with breaches costing an average of over $6 million per incident, according to IBM data, and taking months to detect and contain. These statistics highlight the urgent need for defenses tailored to industrial environments, where downtime can be catastrophic.

Technical challenges further complicate adoption, particularly the incompatibility of legacy OT systems with modern security tools. Many existing infrastructures lack the architecture to support advanced encryption or intrusion detection, creating blind spots in network visibility. PGP Glass tackled this by adopting specialized platforms to gain insight into its OT assets, yet such solutions remain out of reach for many smaller firms due to cost and complexity.

Regulatory compliance adds another layer of difficulty, as industries must navigate stringent standards like ISO 27001 while implementing new technologies. Market limitations, including a general lack of security maturity among manufacturers, also hinder progress. Addressing these obstacles requires a concerted effort to develop accessible tools and foster a culture of cybersecurity awareness across the sector.

Looking Ahead: Future Potential and Considerations

The future of OT and IoT convergence holds immense promise, particularly with anticipated breakthroughs in cybersecurity frameworks. Emerging unified security strategies aim to integrate IT and OT defenses seamlessly, reducing vulnerabilities and enhancing resilience. These advancements are expected to become more widespread over the coming years, offering a blueprint for safeguarding interconnected industrial systems.

Automation is another area poised for growth, with Industry 4.0 technologies set to deepen the impact of convergence on manufacturing efficiency. Innovations like autonomous decision-making systems could further reduce human intervention, streamlining operations while maintaining precision. The expansion of such capabilities will likely redefine competitive benchmarks in the sector, rewarding early adopters with significant advantages.

Sustainability will also play a central role, as firms increasingly leverage IoT data to minimize environmental footprints. The trajectory of PGP Glass, with its focus on renewable energy and real-time monitoring, serves as a model for balancing profitability with responsibility. As these trends mature, the convergence of OT and IoT stands to become a defining force in shaping resilient, efficient, and eco-conscious industrial landscapes.

Final Reflections

Reflecting on this exploration of OT and IoT convergence, it is clear that the technology has already proven its worth in revolutionizing industrial operations with remarkable efficiency gains and data-driven precision. The journey of PGP Glass illustrates how strategic integration delivers tangible benefits, from substantial energy savings to enhanced operational agility. Challenges like cybersecurity risks and legacy system constraints are evident, yet they are met with innovative solutions that strengthen overall resilience.

Moving forward, industries should prioritize investing in tailored security platforms to protect against evolving threats, ensuring that connectivity does not come at the expense of safety. Collaborative efforts to standardize integration practices could also democratize access to these technologies, empowering smaller players to compete. Ultimately, embracing continuous learning and adaptation will be key to harnessing the full potential of this convergence, paving the way for a smarter, more secure industrial future.