For decades, the factory floor has been a digital Babel, a landscape where sophisticated machinery from different manufacturers speaks mutually unintelligible languages, creating costly data silos and operational bottlenecks that have significantly hampered progress. This entrenched system, known as vendor lock-in, forces manufacturers into rigid, proprietary ecosystems where integrating new equipment or software becomes a complex and expensive ordeal. The traditional approach of creating bespoke, point-to-point connections for each piece of machinery has proven to be a major impediment to the agility and scalability required for modern smart factories. As industries push toward greater automation and the adoption of advanced technologies like artificial intelligence, the limitations of these closed systems have become increasingly apparent. The inability of robots, PLCs, and sensors to communicate seamlessly not only stifles innovation but also prevents companies from harnessing the full potential of their operational data, leaving valuable insights trapped within incompatible formats and protocols.

A New Foundation for Smart Factories

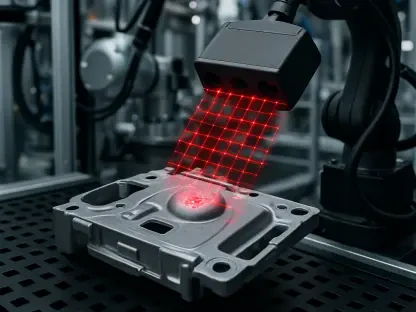

In a decisive move to dismantle these long-standing barriers, Flexxbotics has released its “Flexxbotics Transformers” project to the open-source community, making its comprehensive suite of industrial connector drivers available on GitHub. This initiative strategically employs a software-defined automation (SDA) framework to replace outdated integration models with a flexible “many-to-many” interoperability standard. Functioning as a universal translation layer, the Transformers ensure consistent and reliable communication across an extensive range of factory assets, supporting over 1,000 makes and models of plant machinery, robots, and inspection equipment. The system’s high-performance architecture, built on parallelized, multi-threaded, and asynchronous data pipelines, is specifically designed to handle the high-frequency, multi-modal data streams essential for data-intensive applications like Physical AI and Industrial AI. By making this technology available under a permissive Apache 2.0 license, which allows for unrestricted commercial use, the project empowers companies to build and scale their automation solutions without the artificial constraints imposed by proprietary vendors.

Redefining the Future of Automation

The strategic open-sourcing of industrial-grade connectors marks a pivotal shift away from the fragmented and restrictive ecosystems that have long defined manufacturing technology. This move does more than just provide a technical solution; it fosters a new paradigm of collaboration and shared innovation within the industry. By placing powerful interoperability tools into the hands of developers, integrators, and manufacturers worldwide, the initiative effectively lowers the barrier to entry for creating sophisticated, AI-ready smart factories. The community-driven approach invites contributions that can accelerate the development of new drivers and functionalities, ensuring the platform will evolve to meet the future demands of industrial automation. This transition from closed, proprietary systems to an open, collaborative framework has laid the groundwork for a more agile, efficient, and interconnected industrial future.