In a significant leap for the warehouse and logistics industry, LuminX AI has captured attention by securing $5.5 million in seed funding earmarked for advancing its artificial intelligence (AI) vision models designed to automate and streamline warehouse operations. This development highlights a broader trend toward embracing advanced technologies to enhance efficiency and accuracy in inventory management and operational transparency. Investors such as 1Sharpe, GTMFund, 9Yards, Chingona Ventures, and the Bond Fund have fueled this drive, providing financial backing to a concept that blends vision language models with affordable hardware. LuminX AI’s approach promises to revolutionize how warehouses function by allowing for sophisticated interpretation of video data, thus introducing a new standard in automated inventory control and warehouse management solutions.

Integrating AI Vision Models into Warehouse Operations

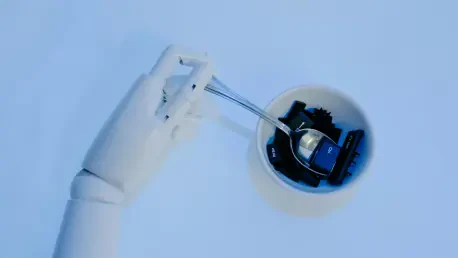

LuminX AI’s innovative technology merges computer vision with natural language processing, enabling the interpretation of complex video data within warehouse settings. These advanced vision language models are designed to close the gap between visual content and linguistic understanding, thereby converting real-time visual information into actionable insights. The AI models demonstrate an exceptional capability to identify essential product details, assess the conditions of packages, and monitor the movements of items through the warehouse. Such capabilities ensure that operational processes can be streamlined, with real-time data providing a comprehensive view that minimizes human error and boosts operational efficiency.

The practical application of these models is enhanced through integration with low-cost mobile hardware cameras. This approach ensures that sophisticated AI technology becomes accessible and adaptable for use from the smallest to the most complex warehouse operations. Whether deployed on docks, conveyor belts, forklifts, or employed as handheld units, this technology enhances automation through real-time data collection and analysis across various operational arms. Alex Kaveh Senemar, an influential figure within the industry, emphasizes how these edge-based vision language models can bring about unprecedented levels of automation, transforming previously opaque procedures into transparent and efficient systems.

Transformative Impact on Logistics and Inventory Management

LuminX AI technology’s ambitious promise revolves around automated dock verification and precise inventory tracking, harnessed through versatile cameras mounted on vehicles, walls, or utilized portably. The accuracy and efficiency of this system remain consistent regardless of variations in speed or angle, ensuring reliable performance across diverse conditions. This technological advancement is reinforced by endorsements from industry leaders like Robert Bascom of Vertical Cold Storage LLC, who lauds the technology for its efficacy in automating critical operational tasks, thereby enhancing quality and substantially reducing claims.

The financial infusion into LuminX AI is poised to accelerate research and development, allowing the technology to be fine-tuned for deployment in edge environments. This not only includes perfecting AI models to handle the vast and variable nature of warehouse operations but also extends to expanding the engineering team and intensifying market reach. Beyond efficiency, the solution represents a shift toward more sophisticated logistics, where artificial intelligence and hardware integration collaborate to optimize tasks that previously depended heavily on manual oversight.

Embracing Future Innovations in Warehouse Automation

LuminX AI is revolutionizing warehouse operations by merging computer vision with natural language processing, allowing for the intricate analysis of video data. Their cutting-edge vision language models bridge the gap between visual content and linguistic concepts, effectively translating live visual information into valuable insights. These AI systems excel in recognizing critical product details, evaluating package conditions, and tracking the movement of goods across the warehouse. By leveraging real-time data, warehouse procedures can be optimized, significantly reducing human error and enhancing efficiency.

Accessible thanks to low-cost mobile hardware cameras, this sophisticated AI technology is adaptable for both small and large warehouse operations. From docks and conveyor belts to forklifts and handheld units, this technology boosts automation while providing real-time data insights for various operational tasks. Industry leader Alex Kaveh Senemar underscores how these edge-based vision language models can drive unprecedented levels of automation, transforming obscure processes into clear and efficient systems.